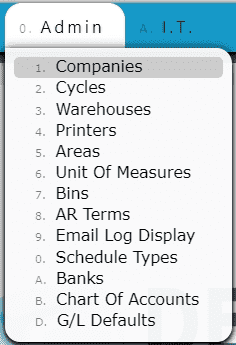

To View Company Preferences:

Note: Company-level preferences will affect the entire company's use of the system, and is setup and maintained by I.T. Contact I.T to make any changes.

What Company Preferences Can Control

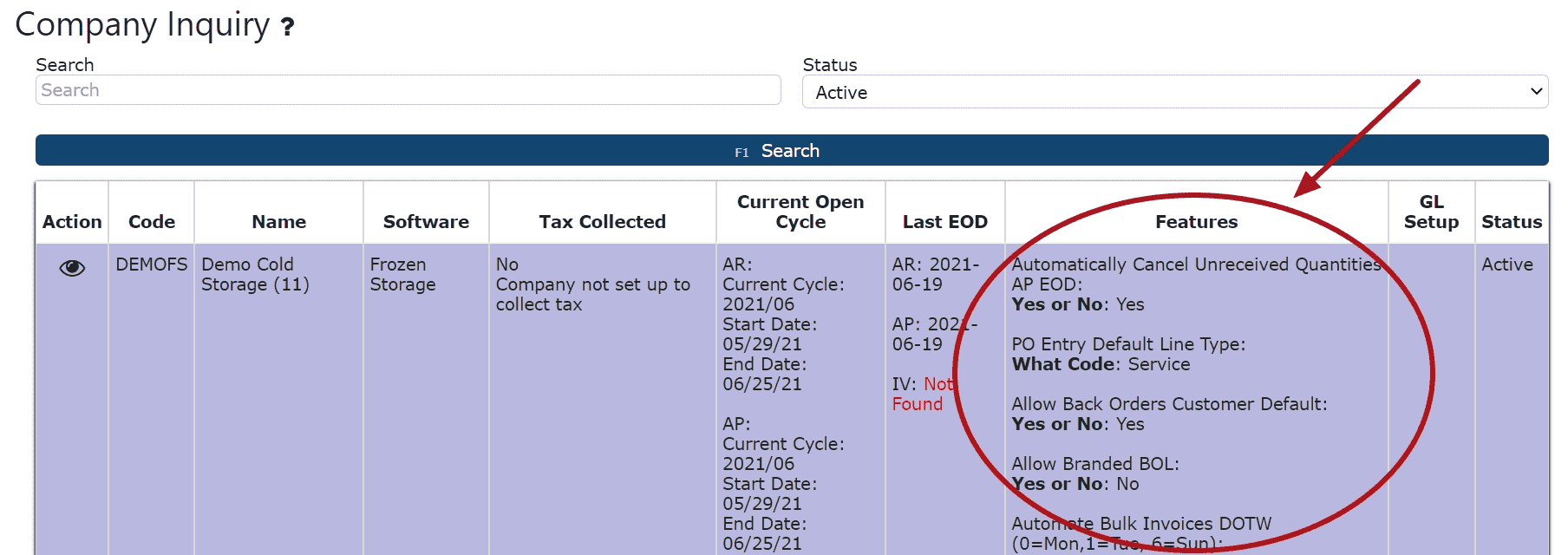

• Automation of frequent tasks

Examples include auto-creating invoices, defaulting warehouse or ship-via selections, auto-applying payment rules, or enabling automated emails for statements, POs, or bulk documents.

• Default behaviors across workflows

Companies can determine how sales orders default, how purchasing behaves, or how system rules apply during receiving, picking, putaway, billing, and other operational processes.

• System-wide validations and restrictions

Preferences can enforce rules that prevent incorrect accounting dates, block duplicate entries, require specific fields, or limit actions based on user role.

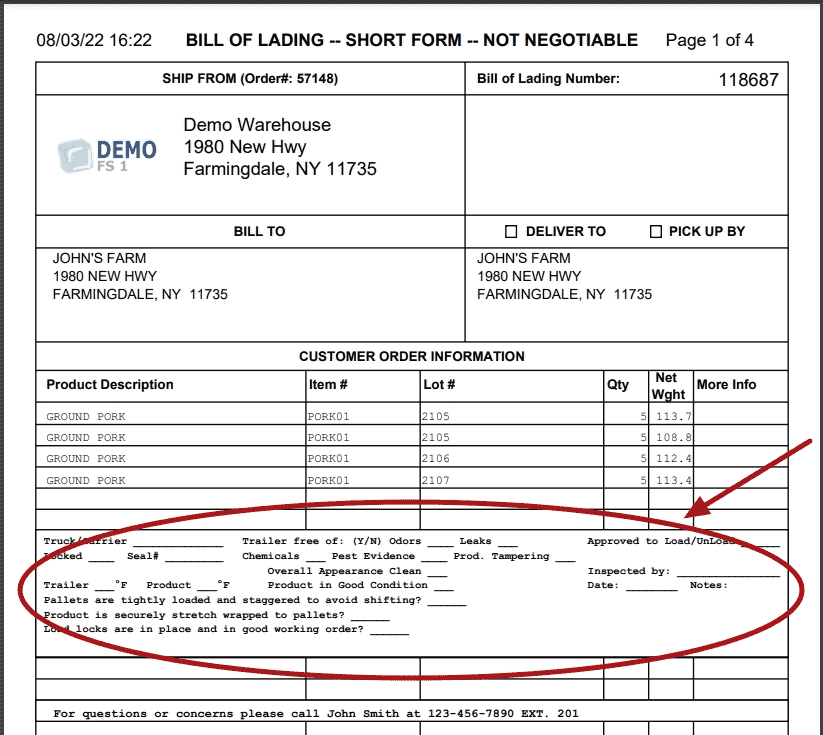

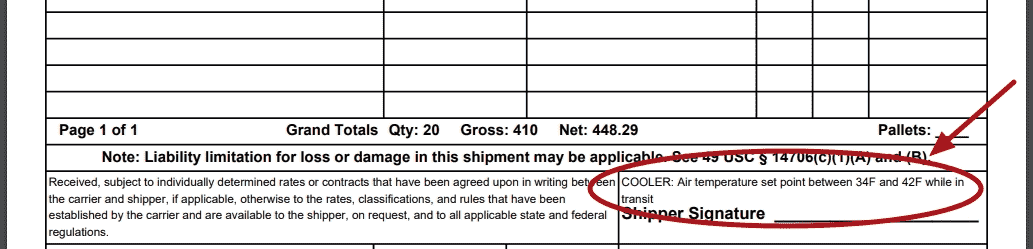

• Warehouse & WMS configuration

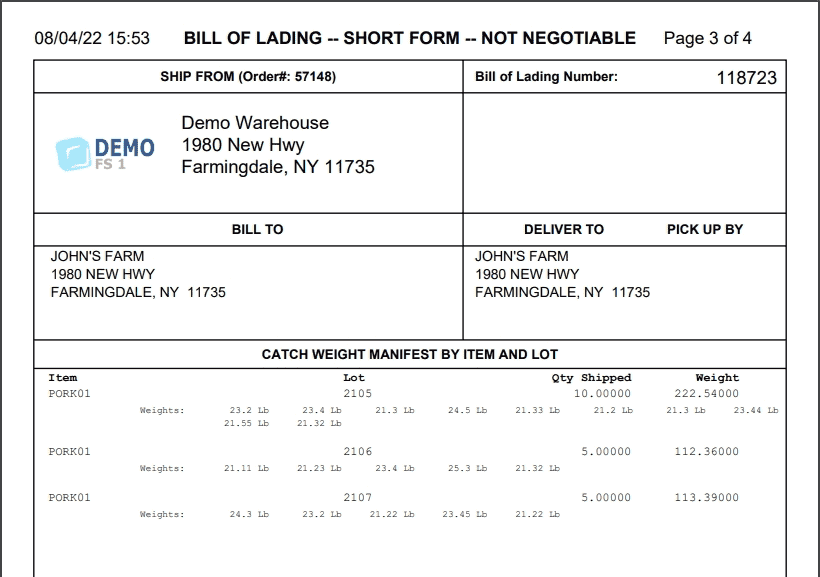

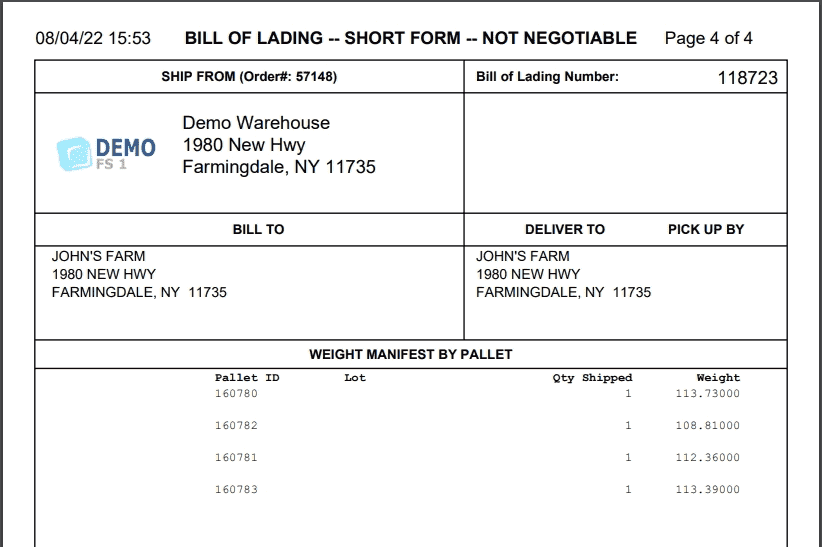

Options may control scanning behavior, pallet/lot handling, inventory allocation, picking strategies, cold storage workflows, and order-staging processes.

• Financial & accounting functionality

Settings influence AR and AP processing, payment applications, statement generation, credit workflows, inventory valuation, and posting rules.

• EDI & communication settings

Preferences determine how inbound/outbound EDI transactions behave, how documents are formatted, and whether automated email or notification processes send specific documents.

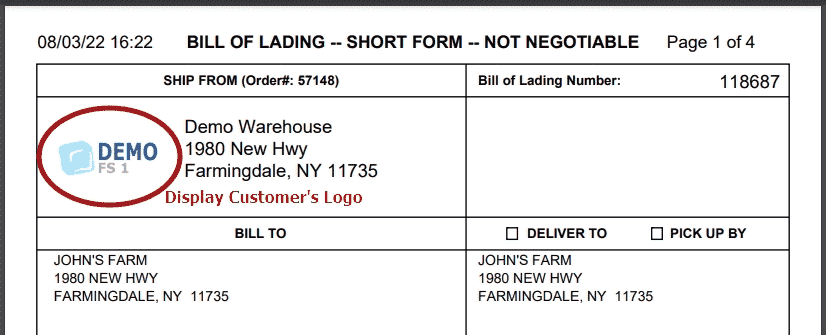

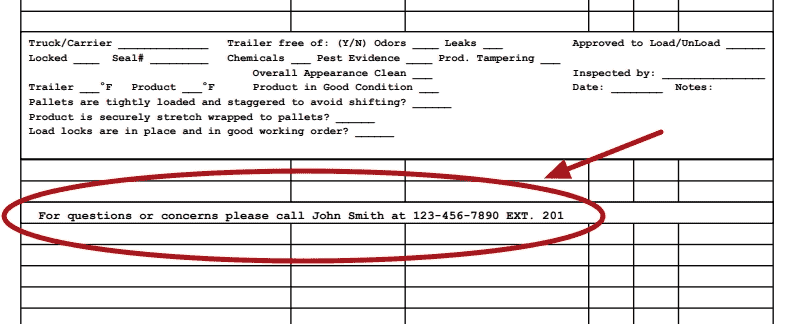

• Document generation & email defaults

Preferences also govern default forms, document layouts, and which documents automatically print or email during sales, purchasing, AR, AP, and WMS operations.

Important Note

Company-level preferences affect the entire organization and should only be updated by your IT department or an authorized system administrator.

If a change is required, please contact IT to ensure the update is reviewed and implemented properly.