Maintaining an Asset:

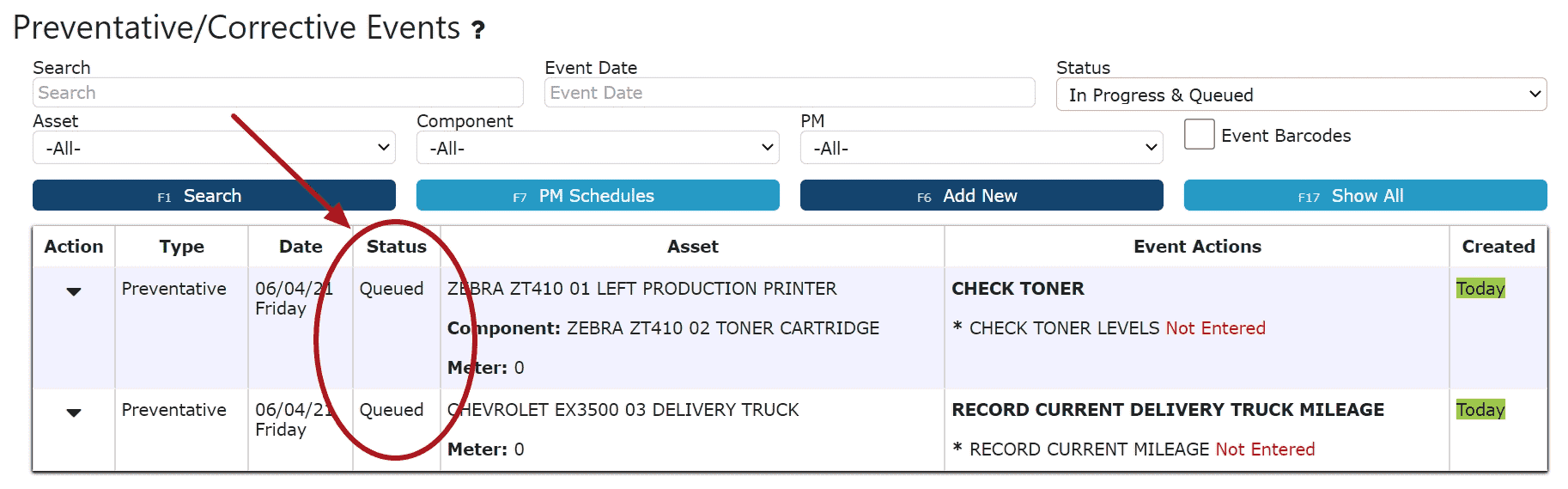

The Asset Maintenance module provides a centralized solution for managing company assets, tracking preventative and corrective maintenance, and ensuring compliance with maintenance schedules and audit requirements. This module allows users to organize equipment, schedule and perform maintenance, manage related documents, and record all maintenance events — both preventative and corrective — directly within the system.Purpose of Asset Maintenance:

• Provides a structured system for organizing and maintaining all company assets and equipment.

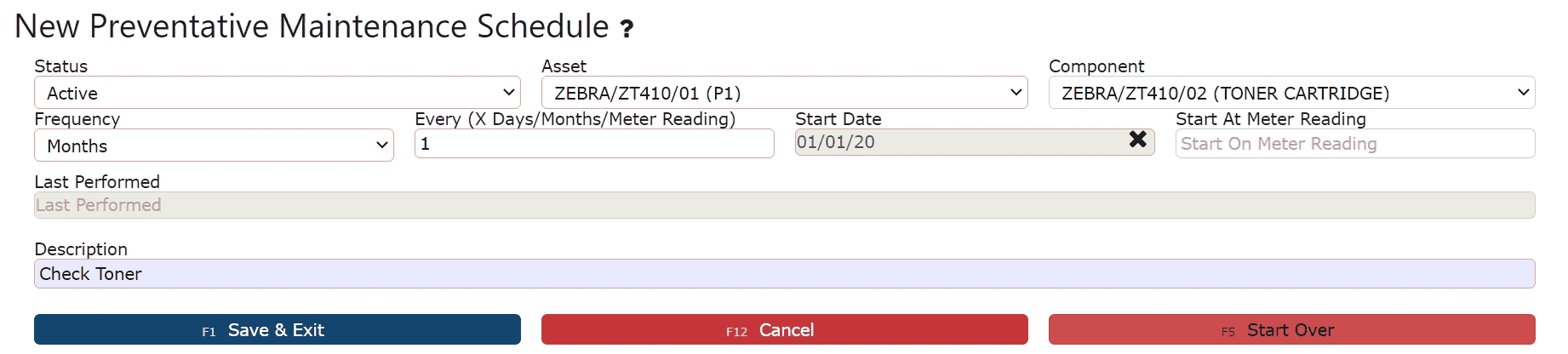

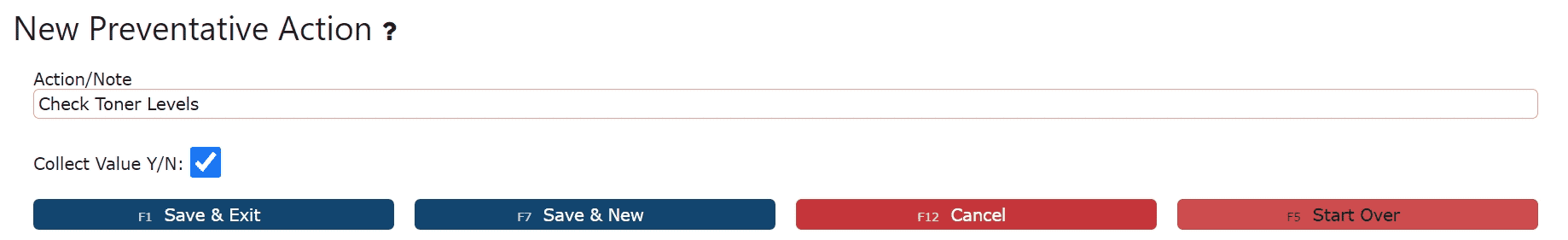

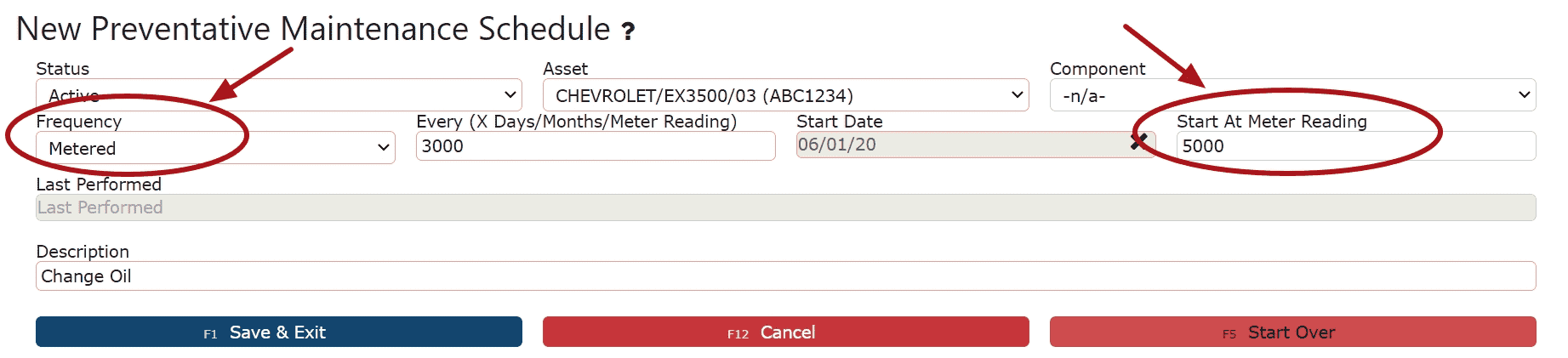

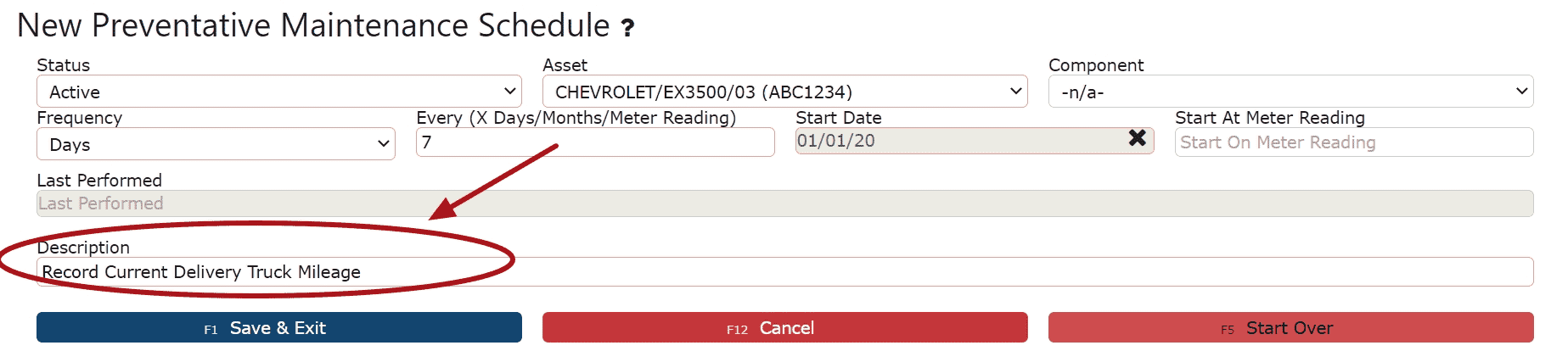

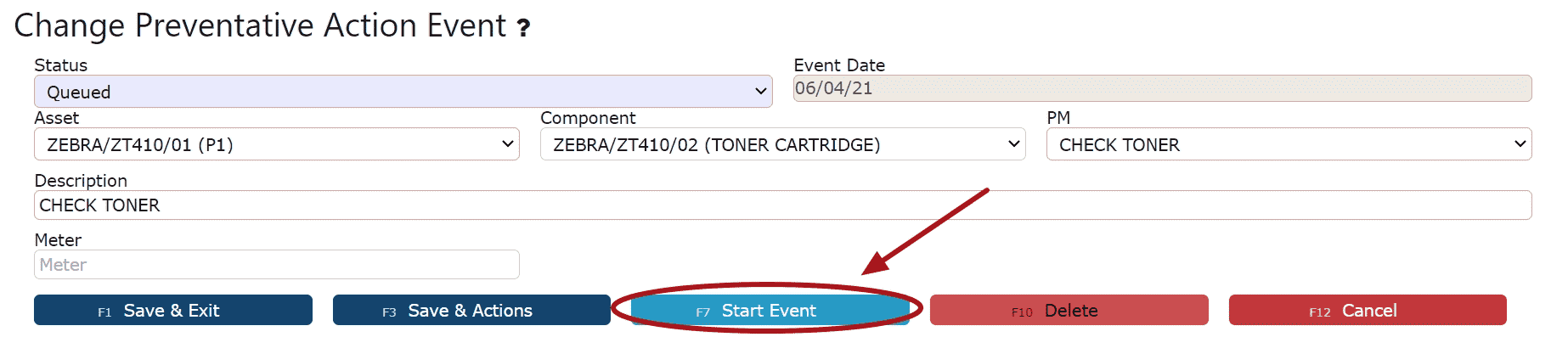

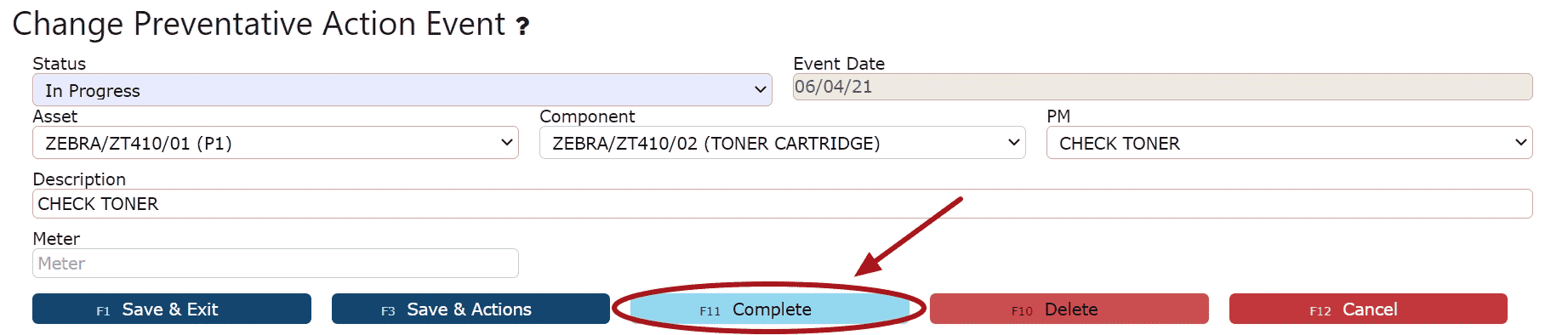

• Ensures maintenance is performed on schedule, helping extend asset lifespan and reduce downtime.

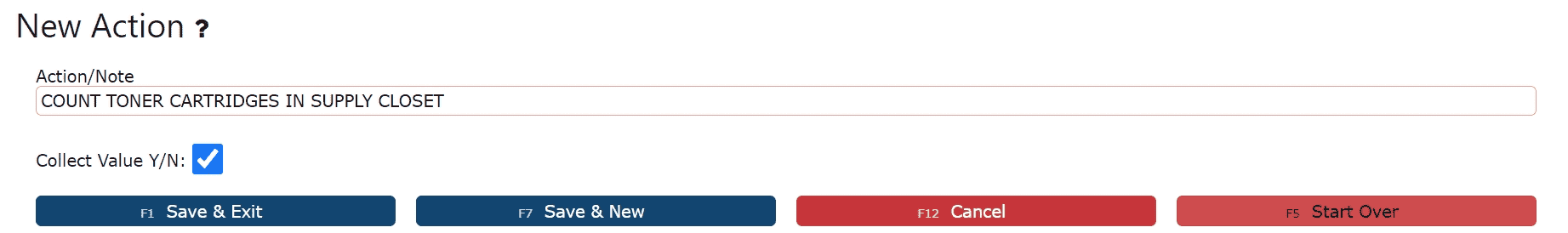

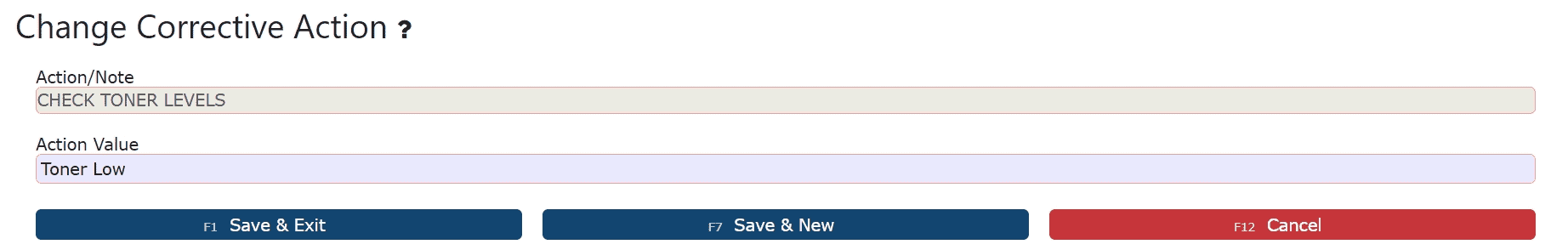

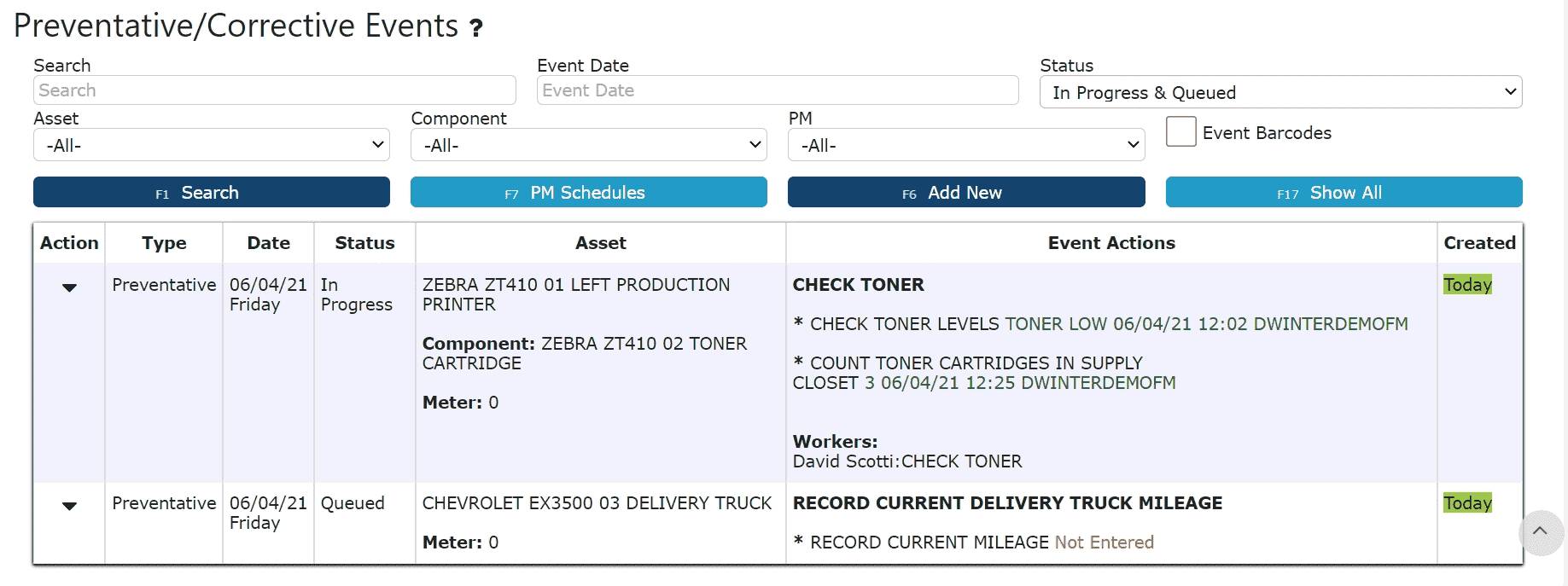

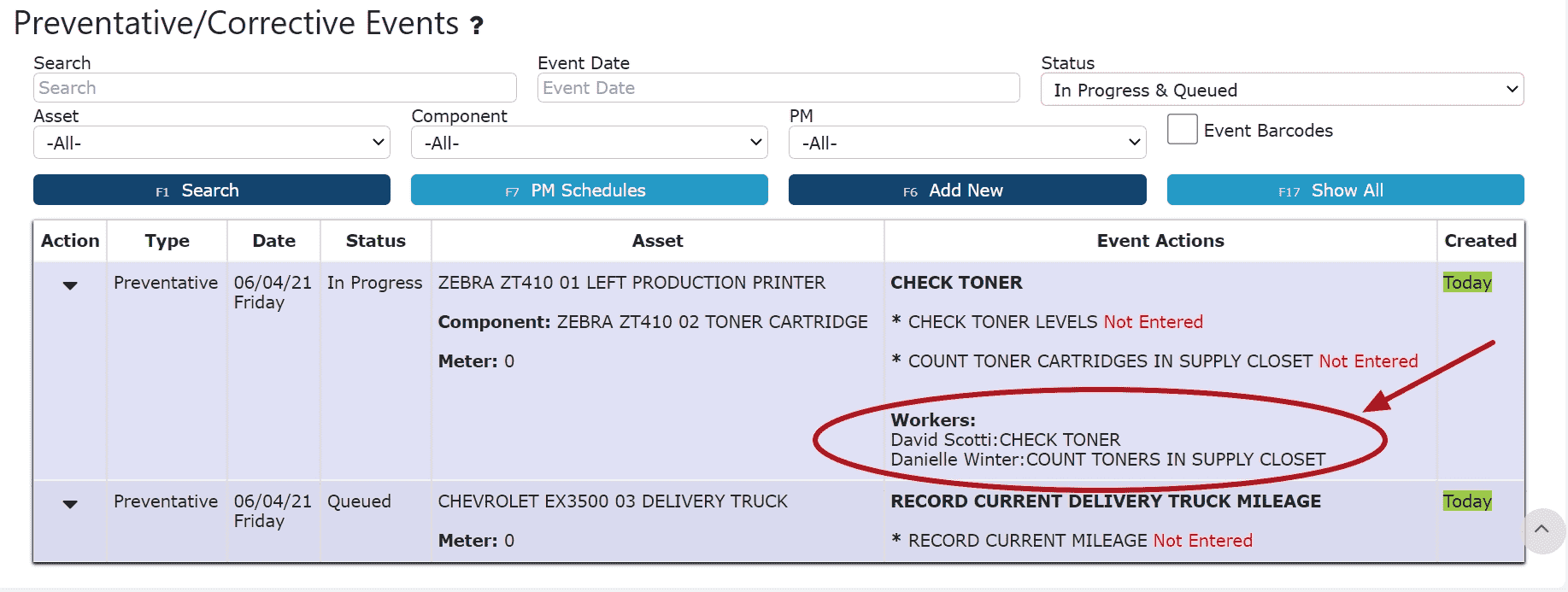

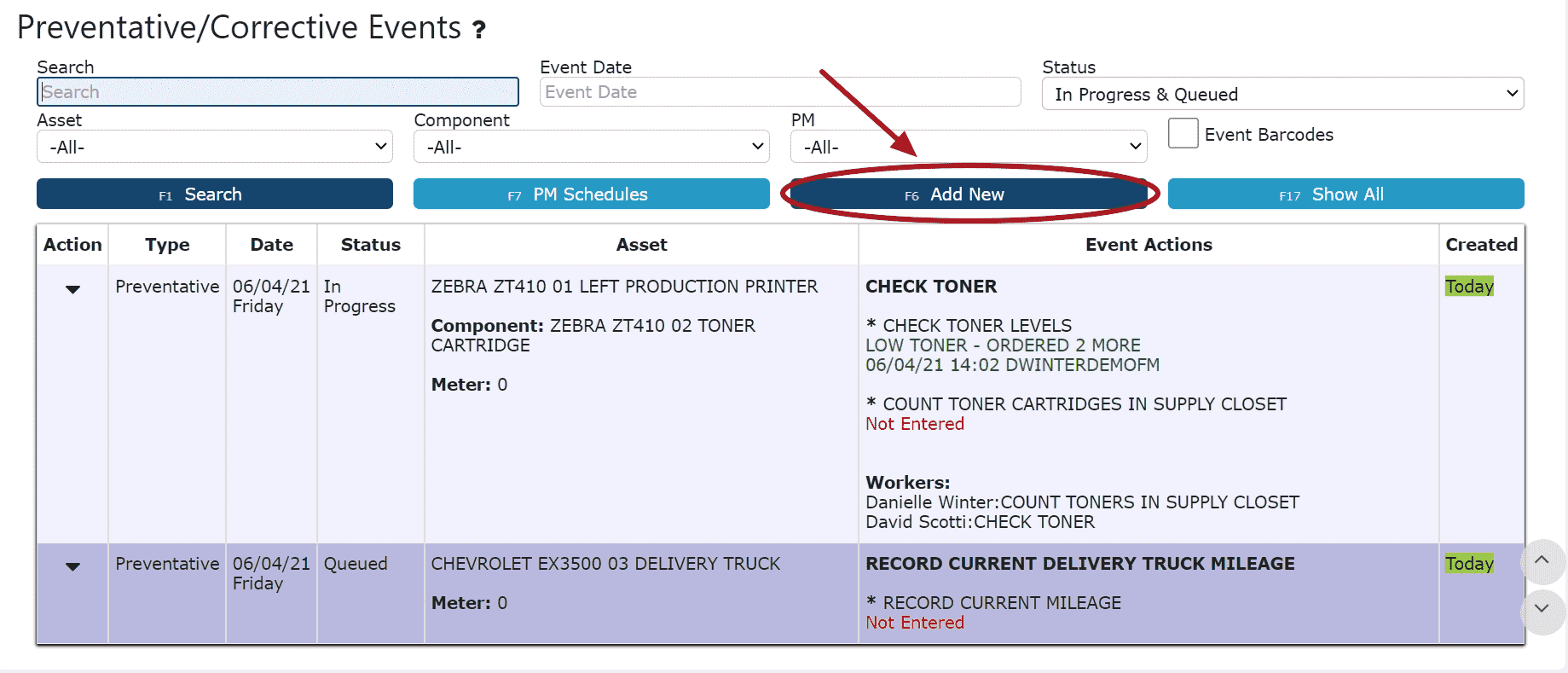

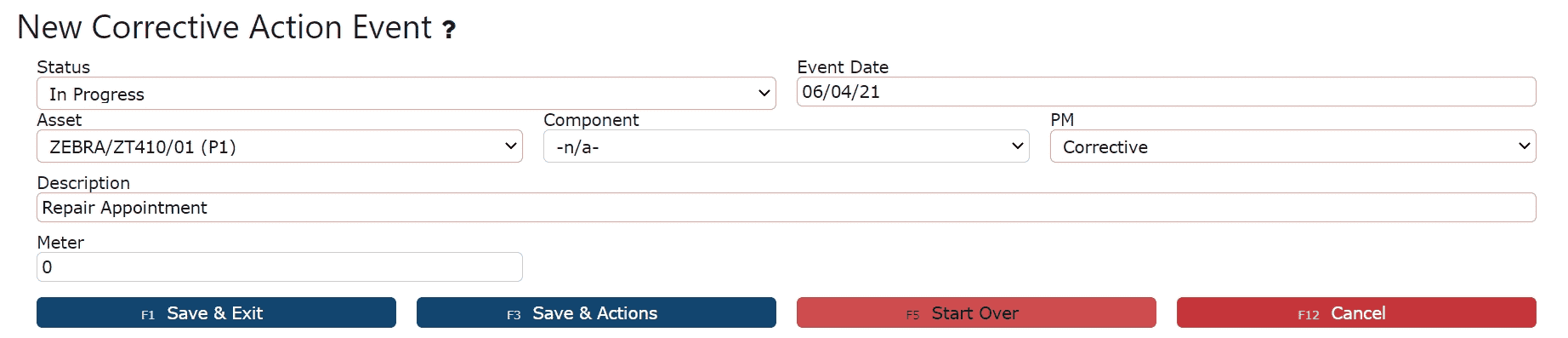

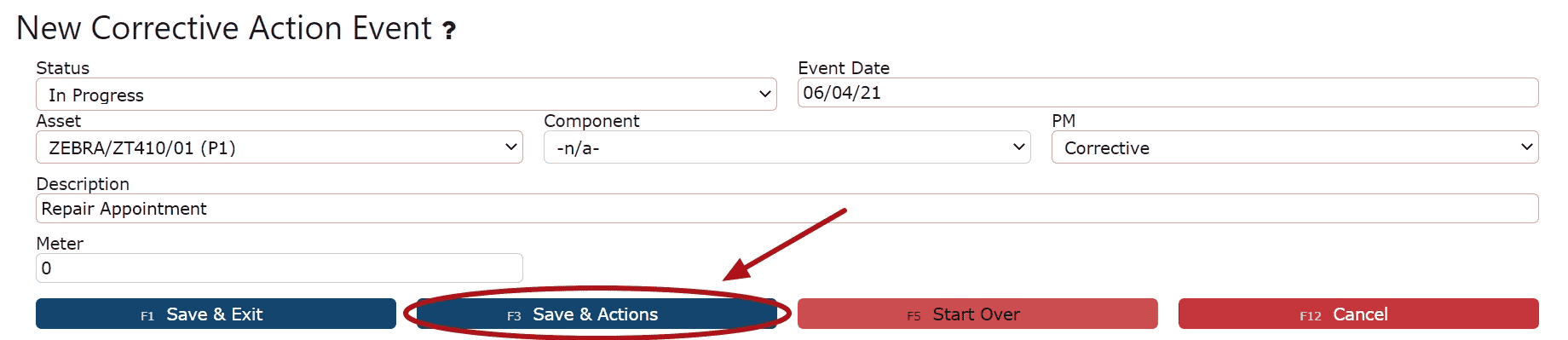

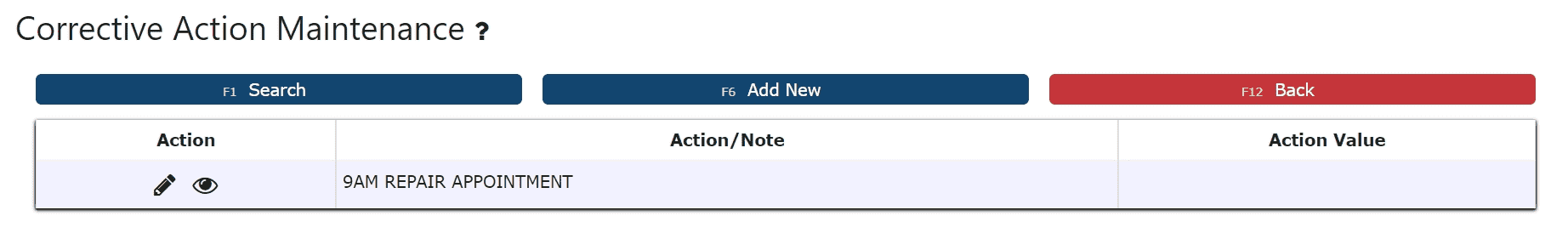

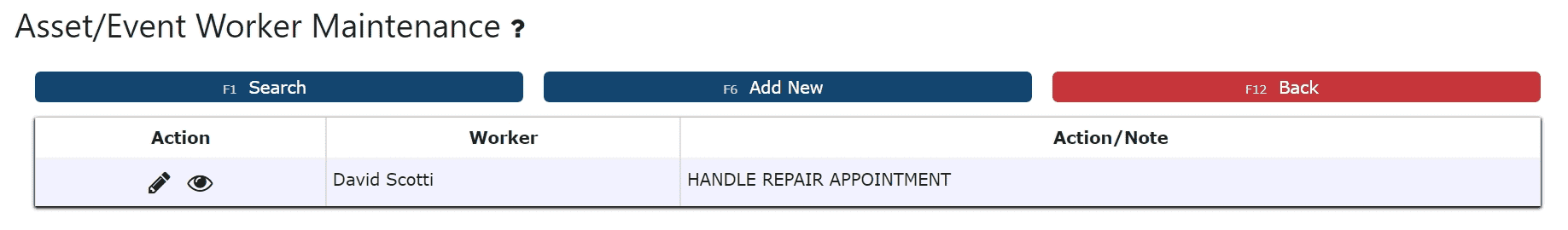

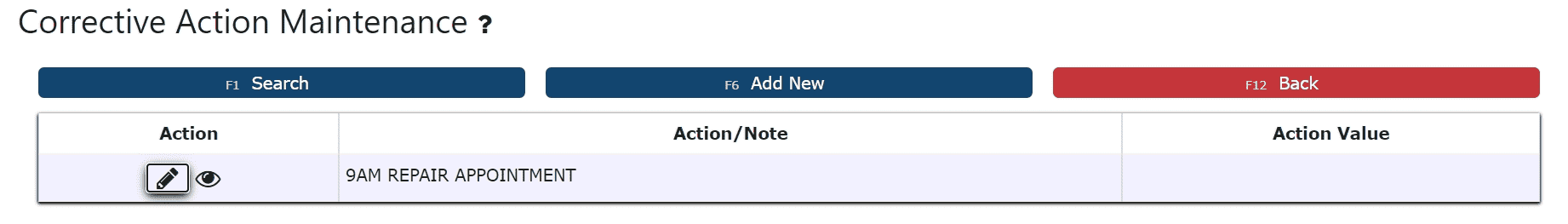

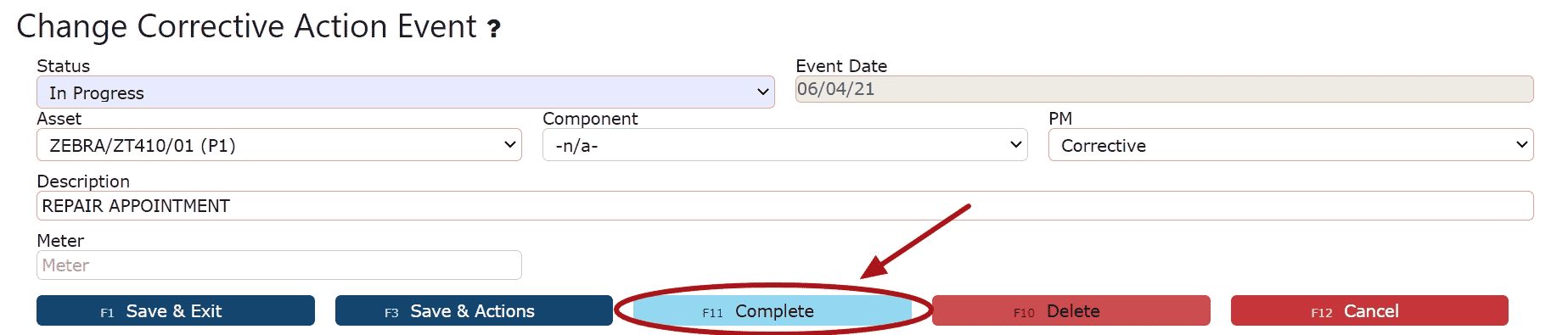

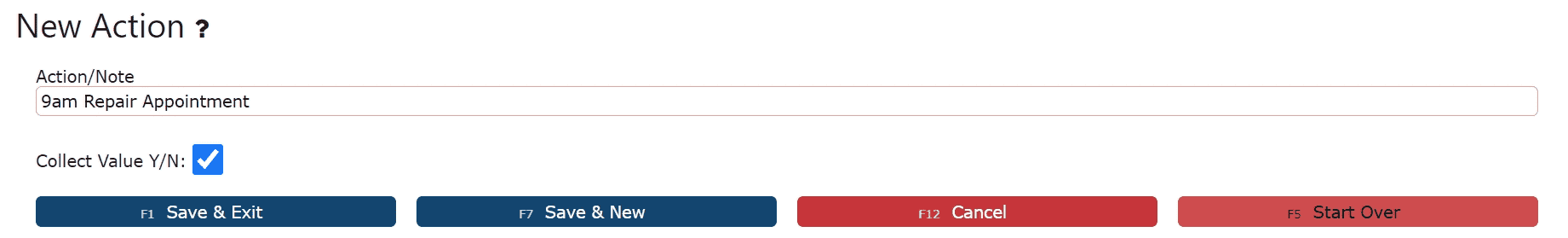

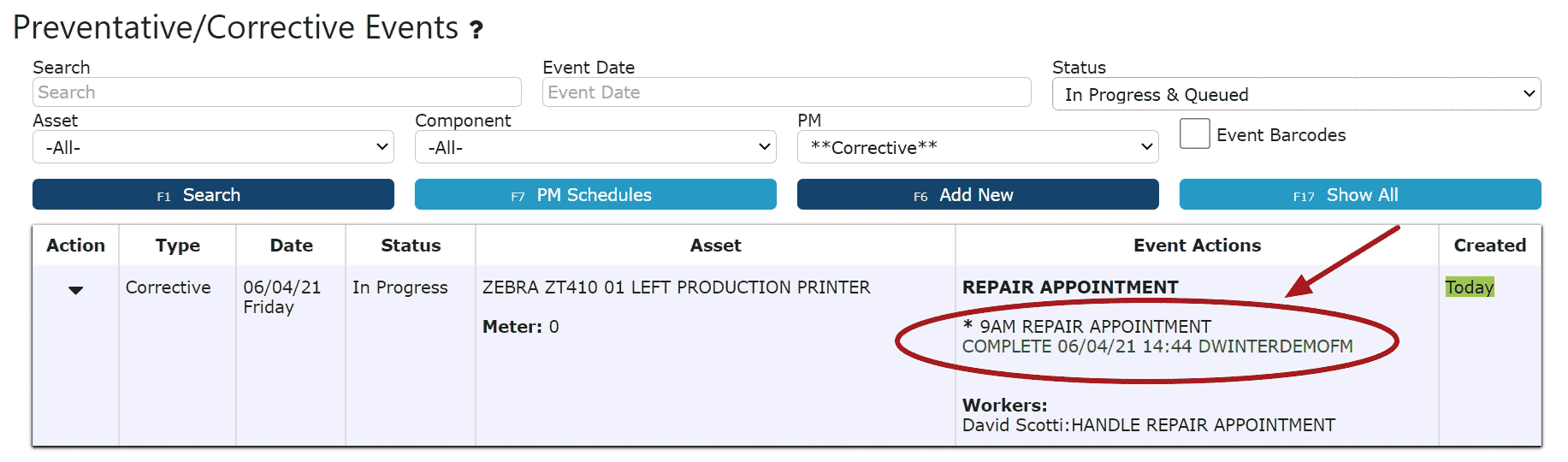

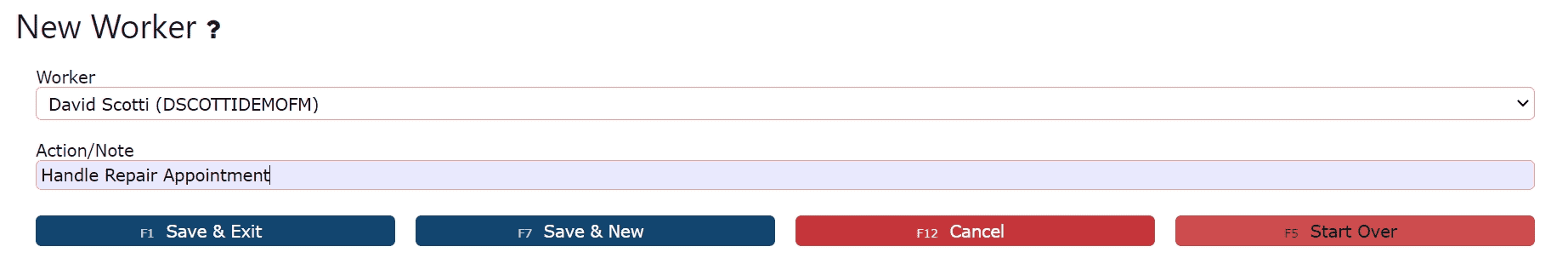

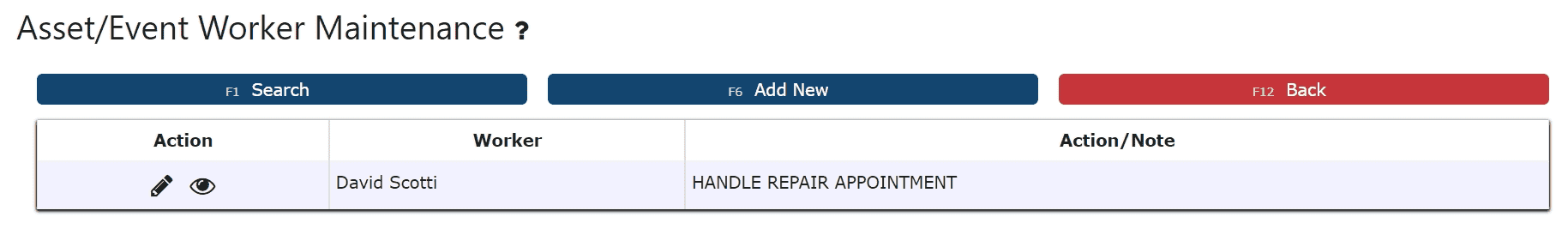

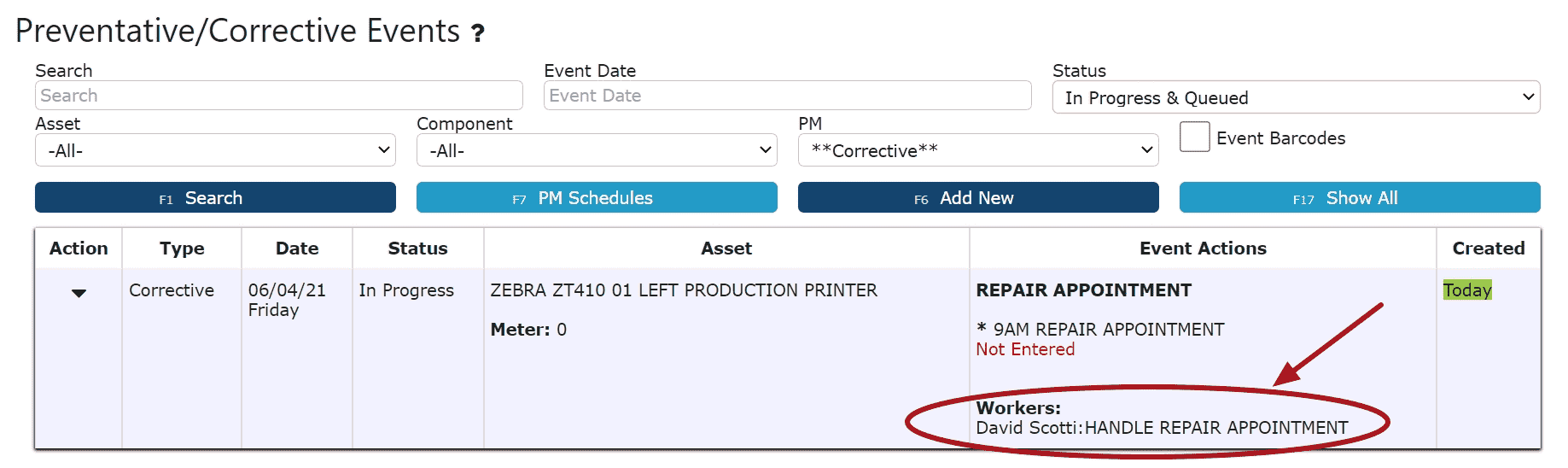

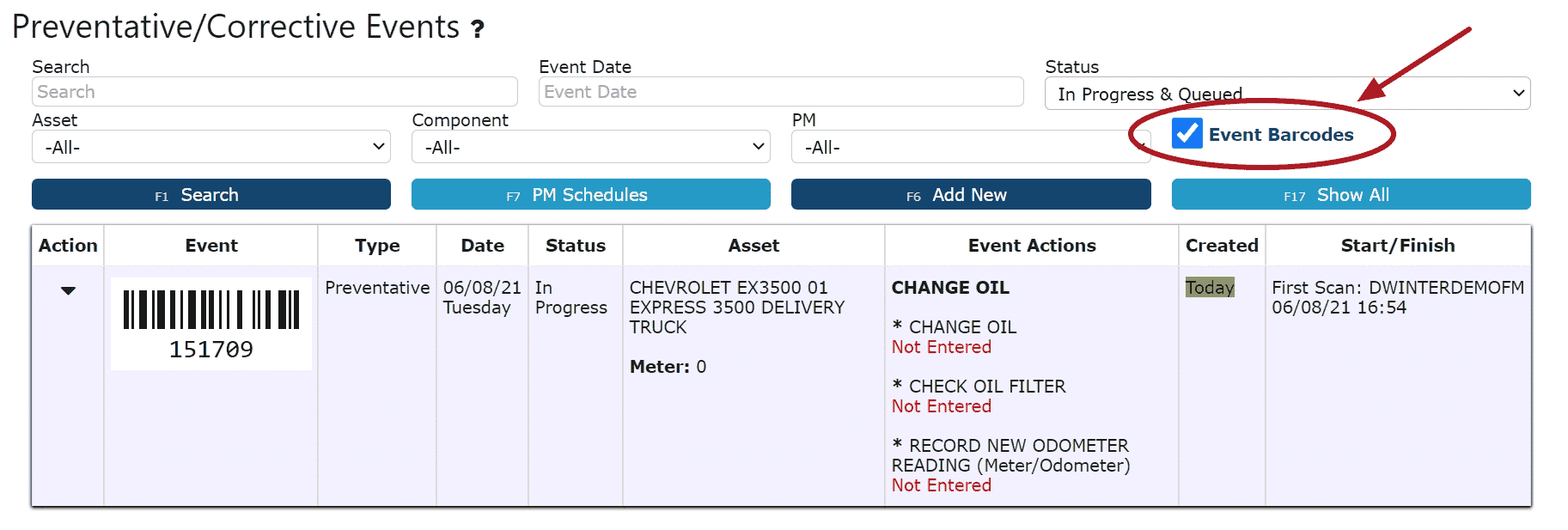

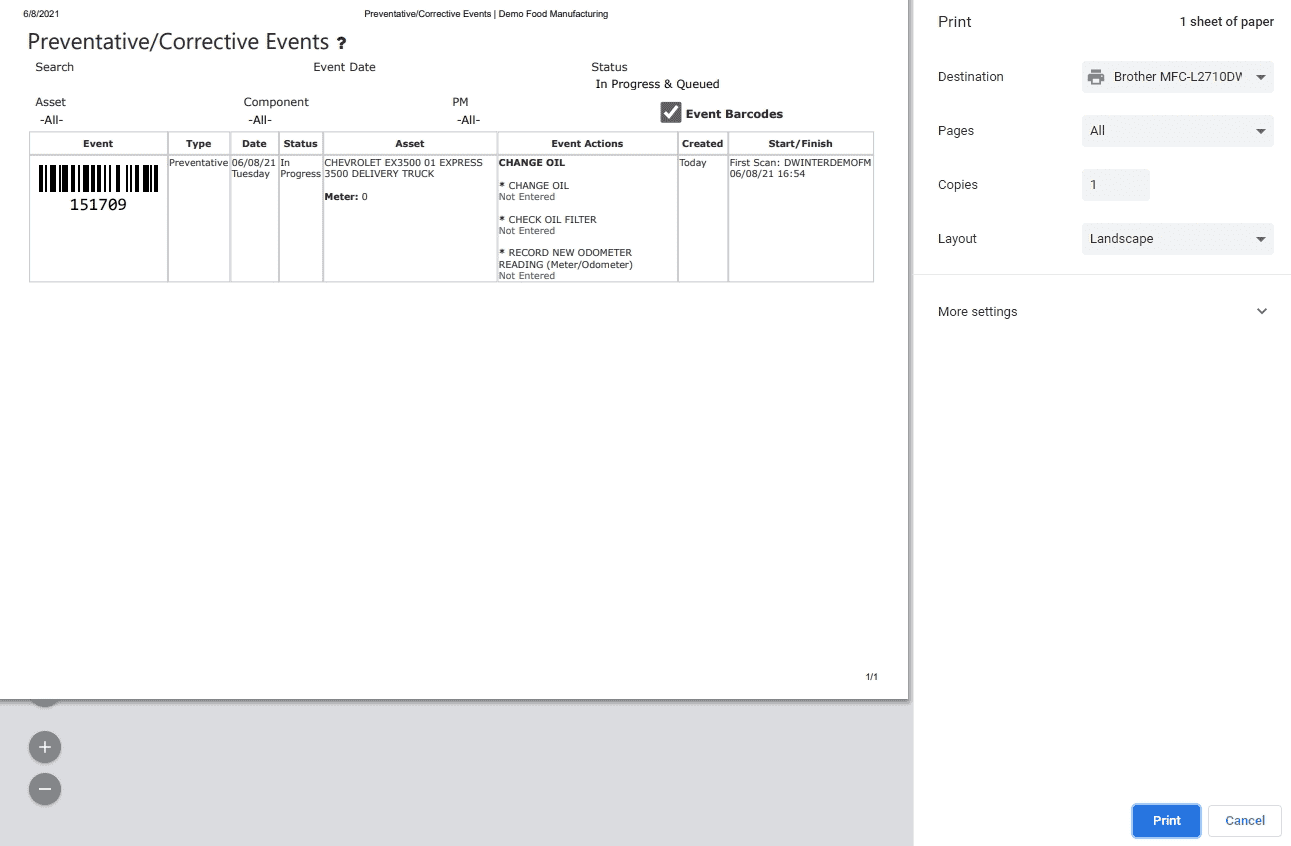

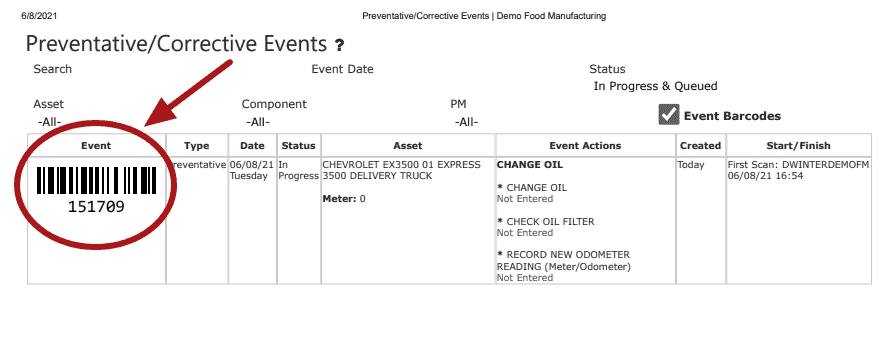

• Tracks preventative and corrective maintenance events for compliance and audit visibility.

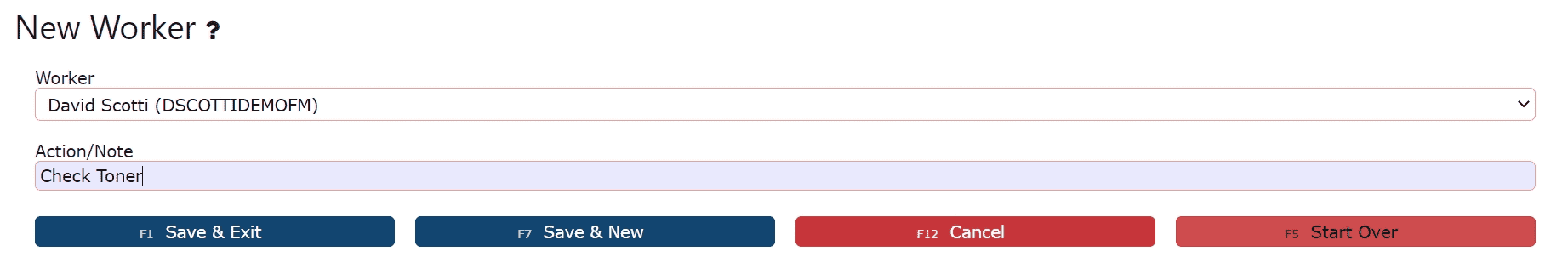

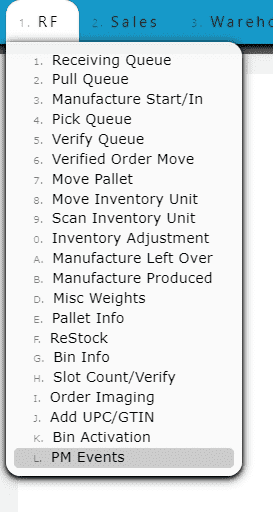

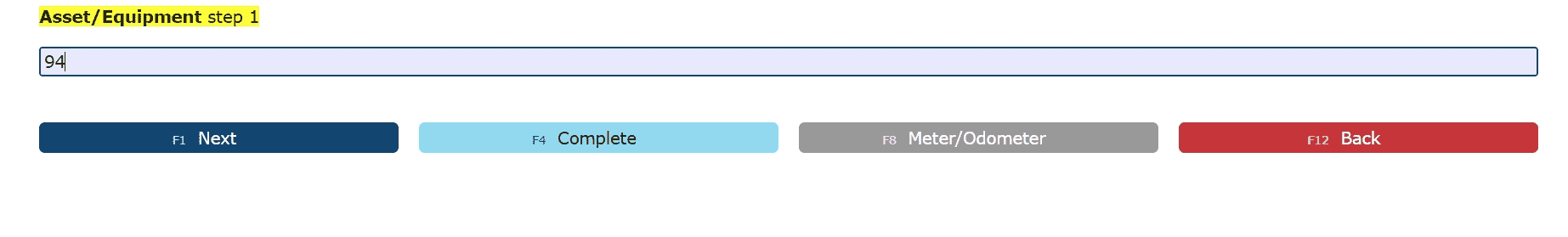

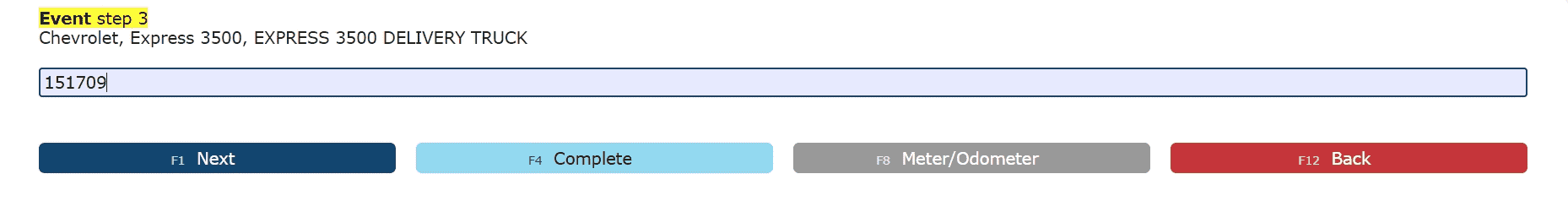

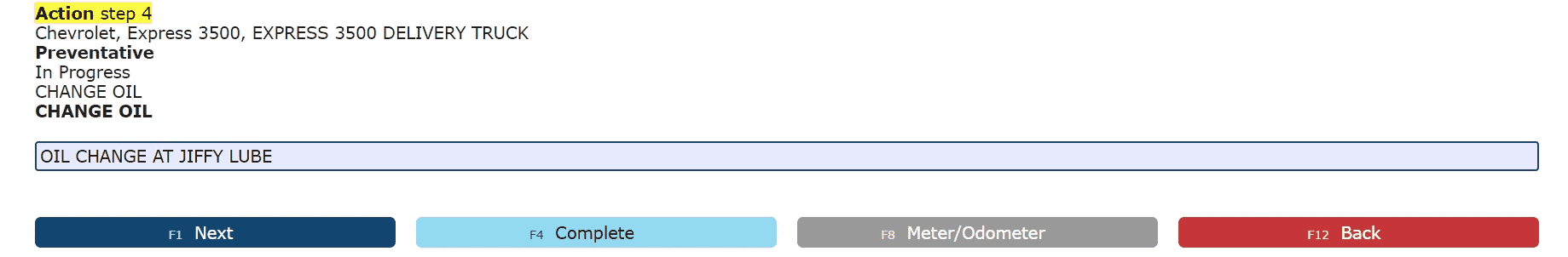

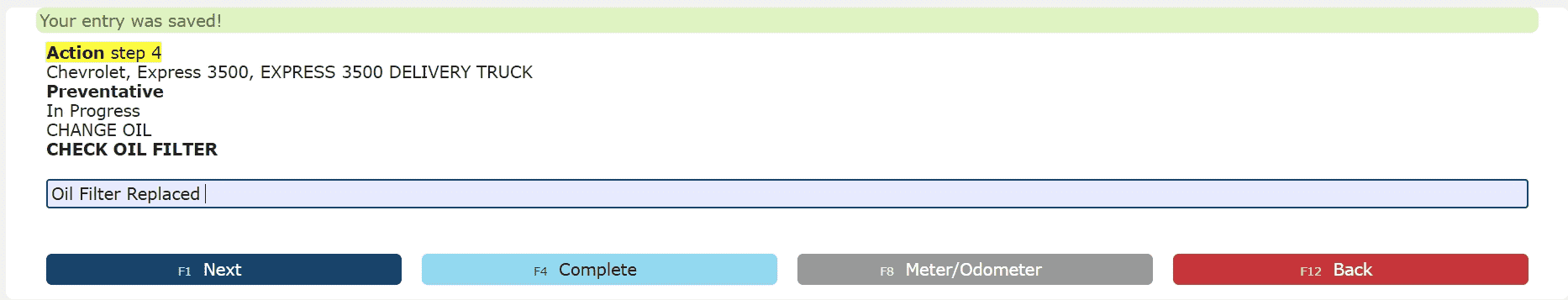

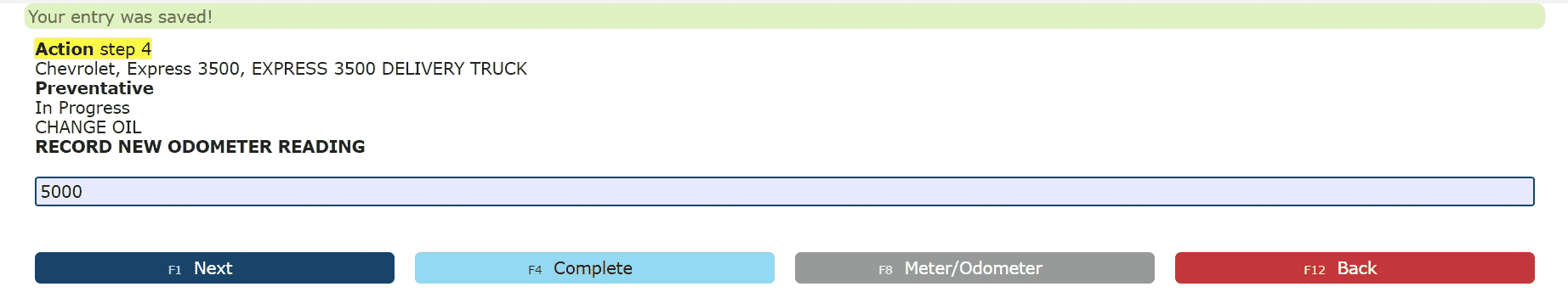

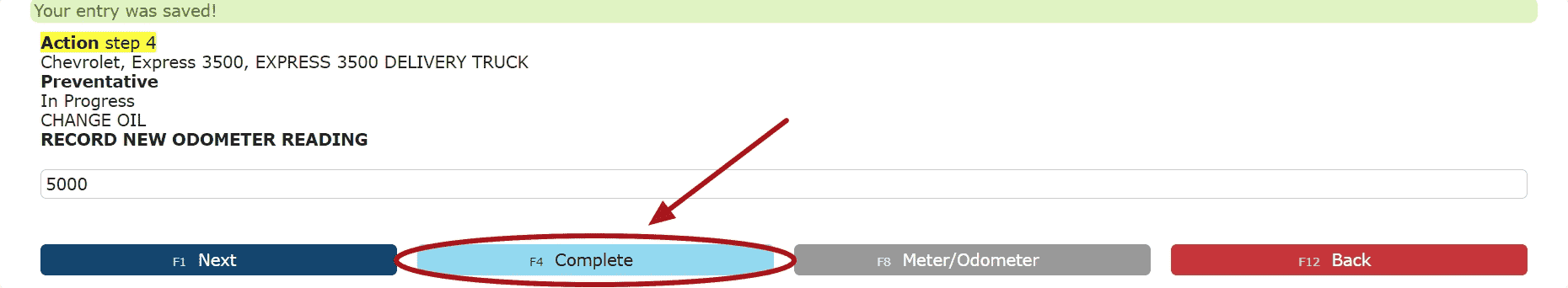

• Supports both manual and RF-based (scan gun) workflows for completing maintenance events efficiently.

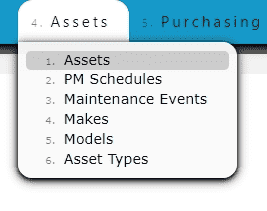

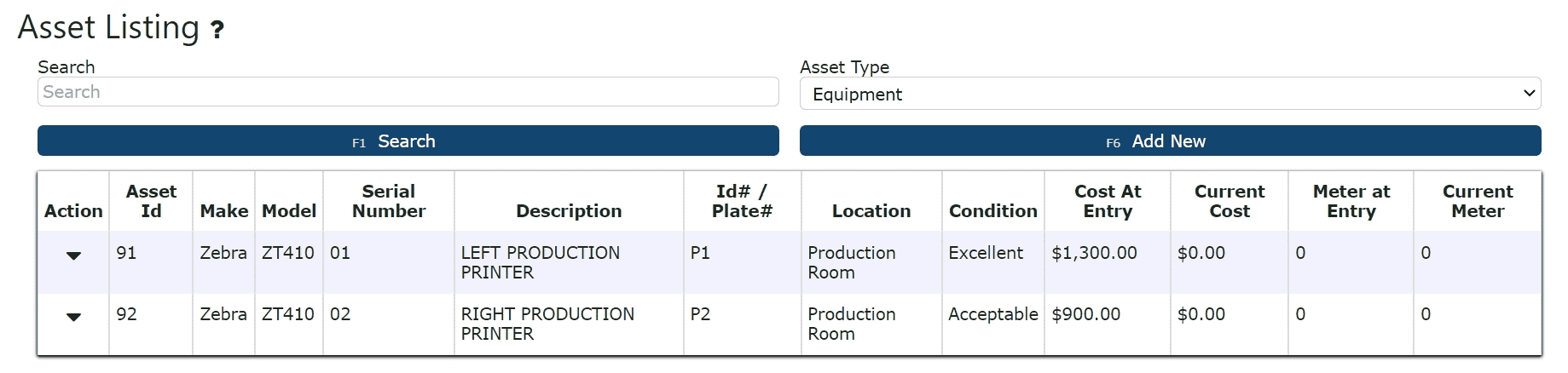

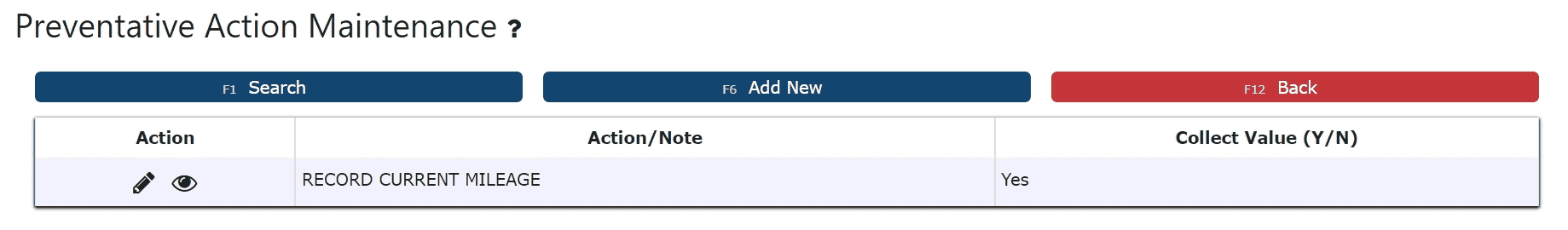

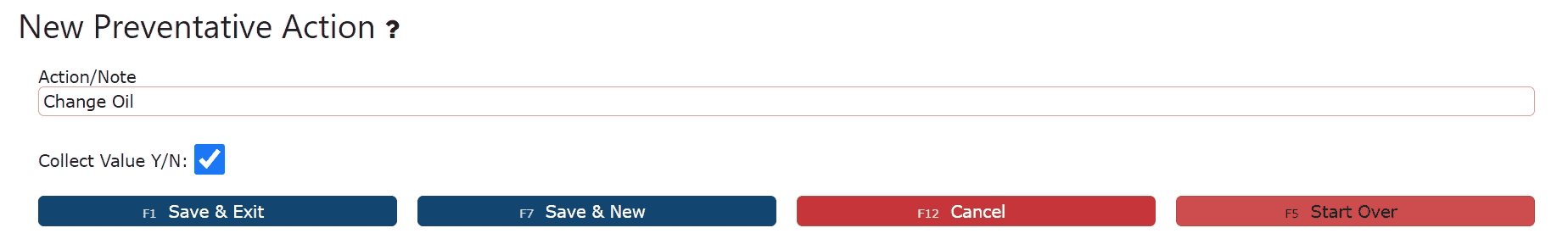

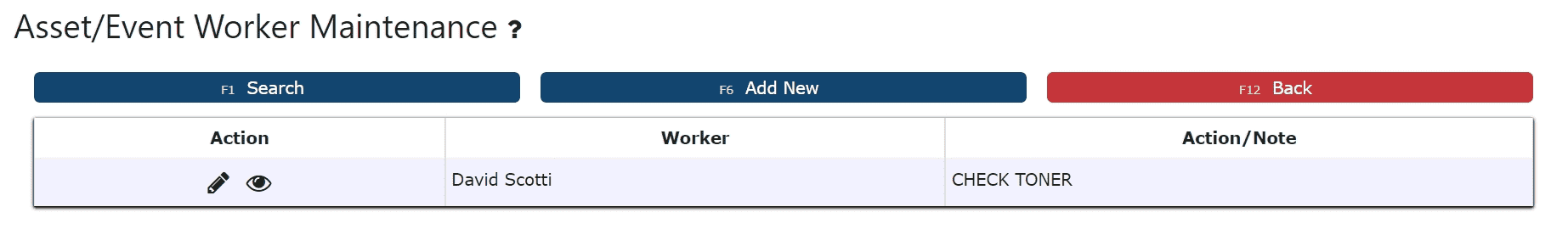

Managing Assets

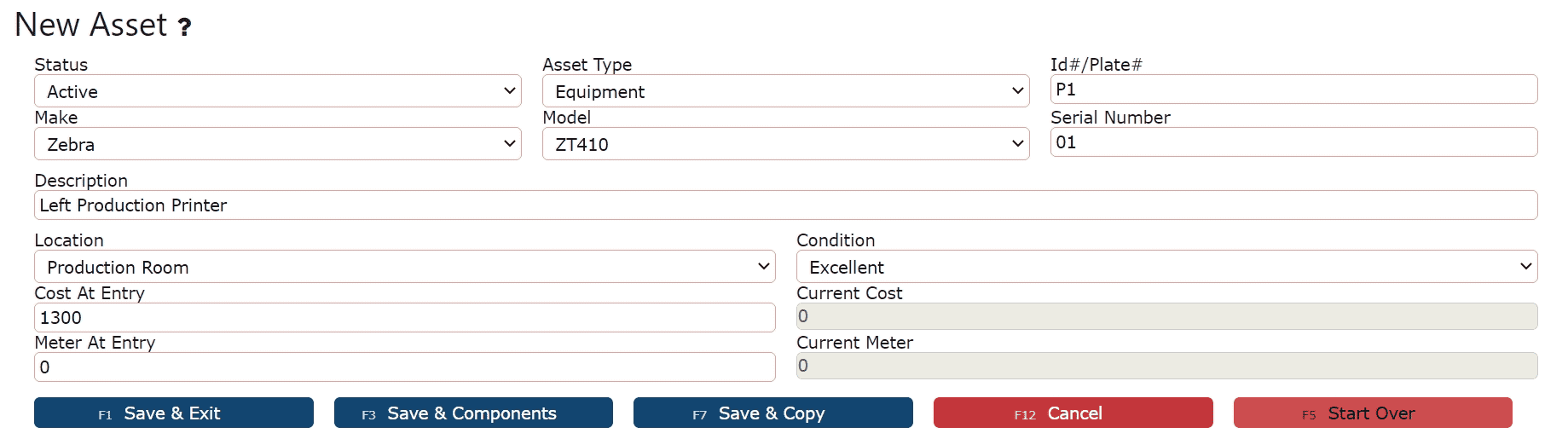

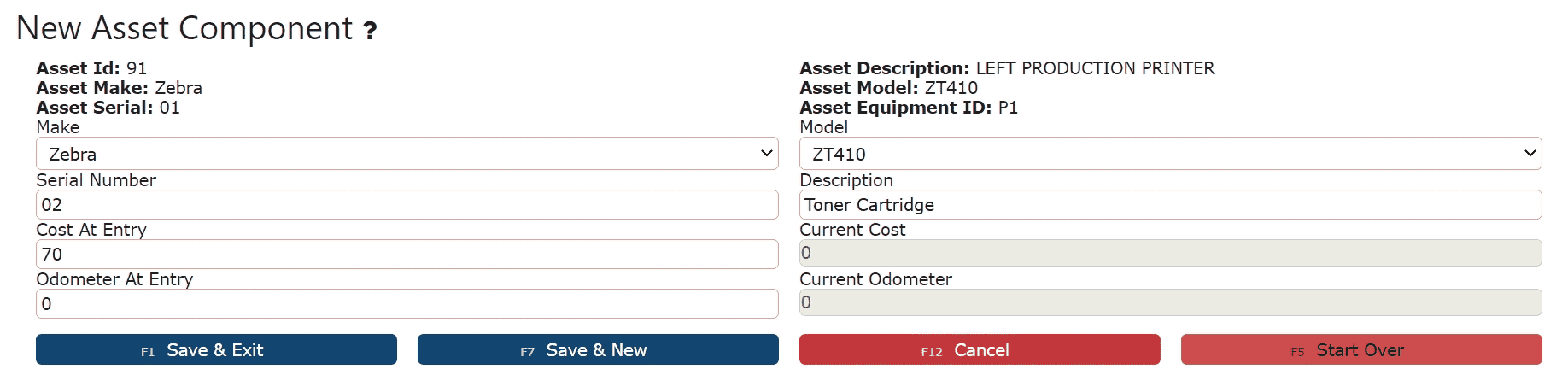

• Maintain a master list of assets and equipment, including all related components.

• Categorize assets by Type, Make, and Model for organized tracking.

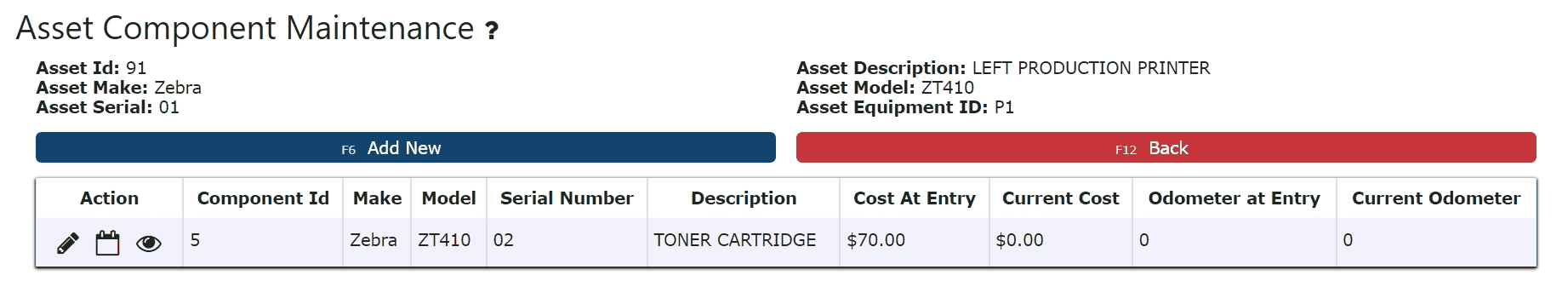

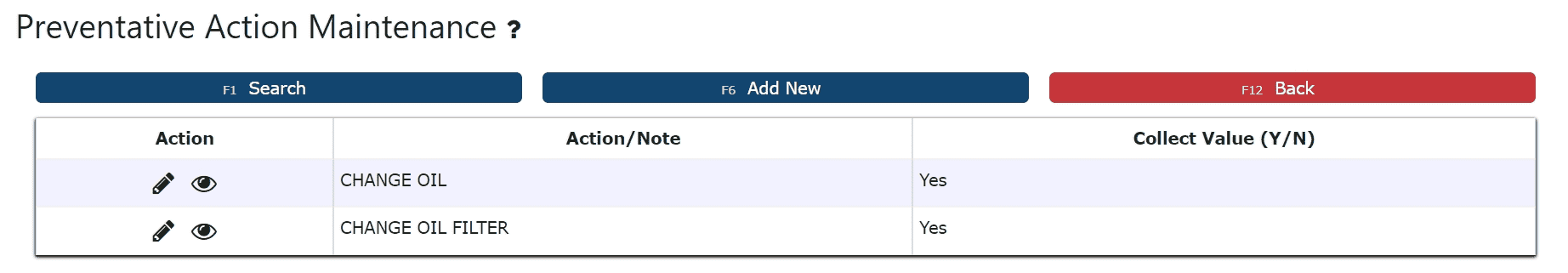

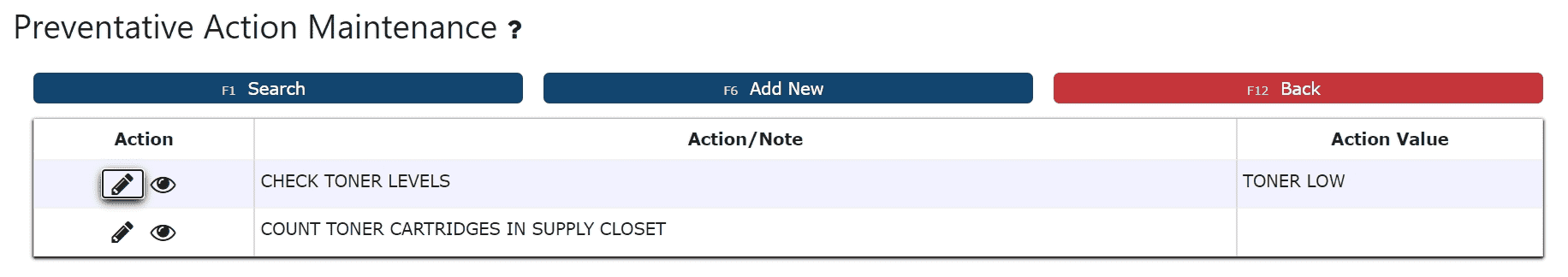

• Assign and manage components tied to each asset that require regular maintenance.

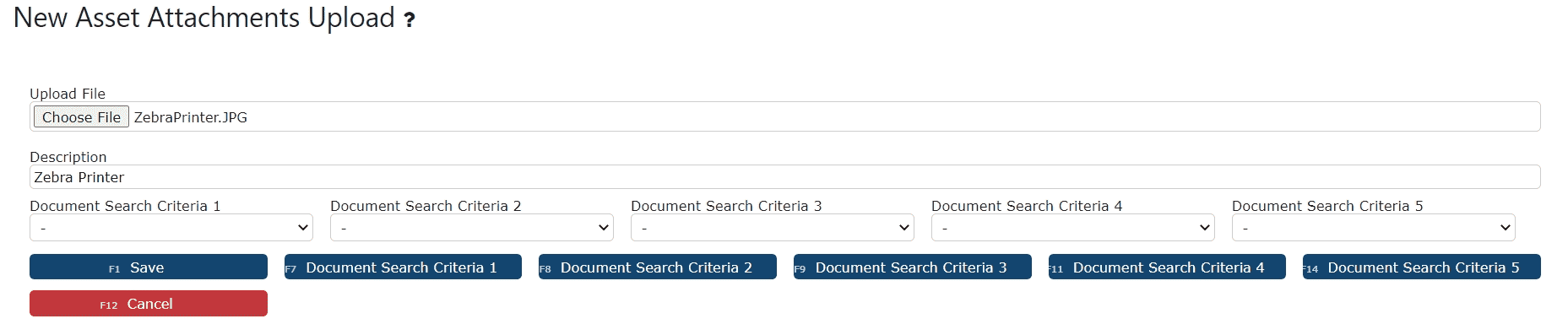

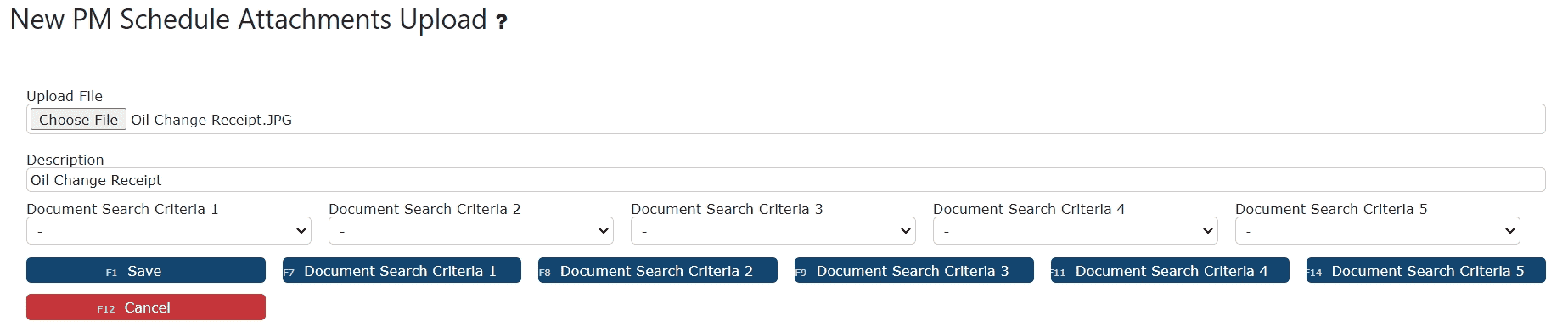

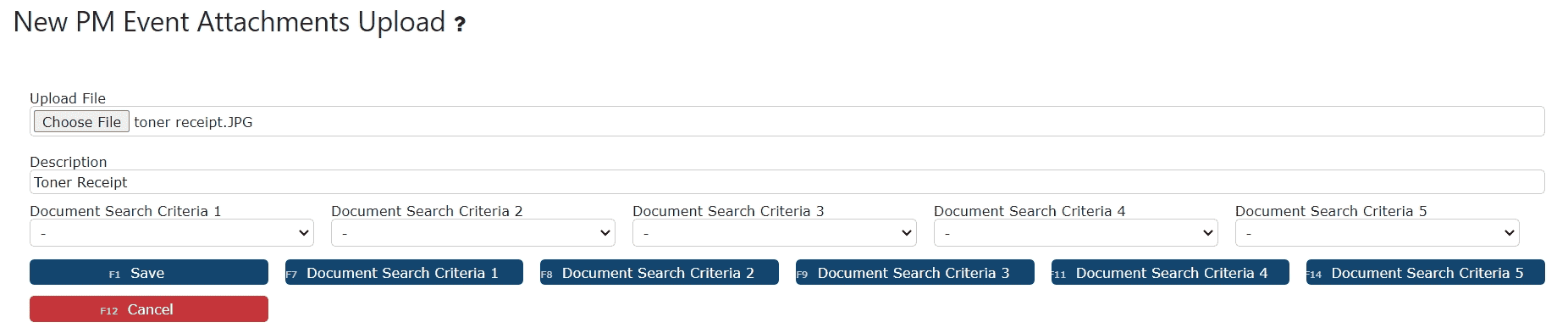

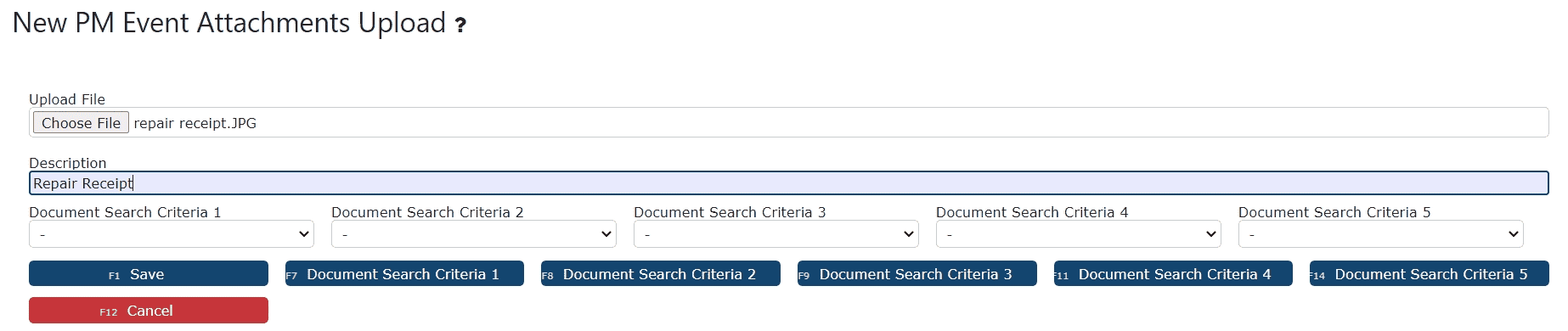

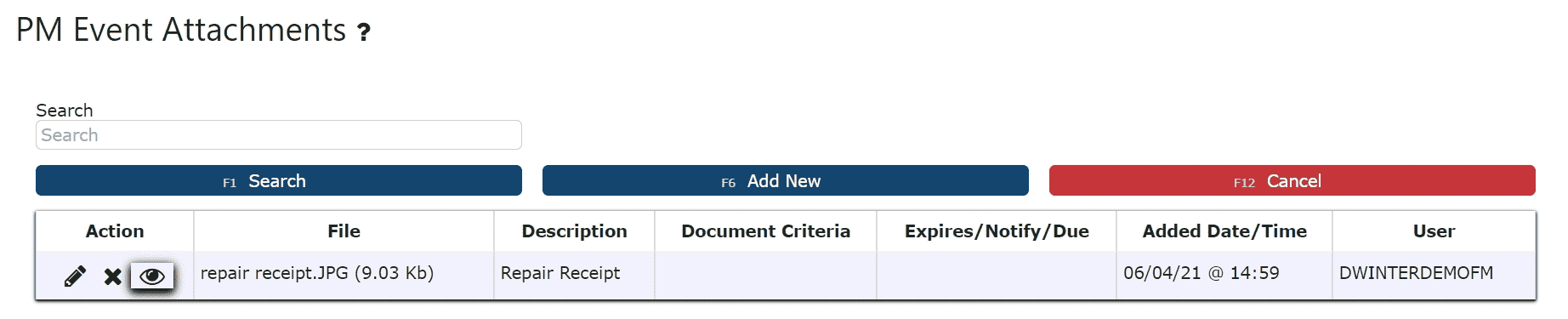

• Add attachments such as images, receipts, or manuals for recordkeeping and quick reference.

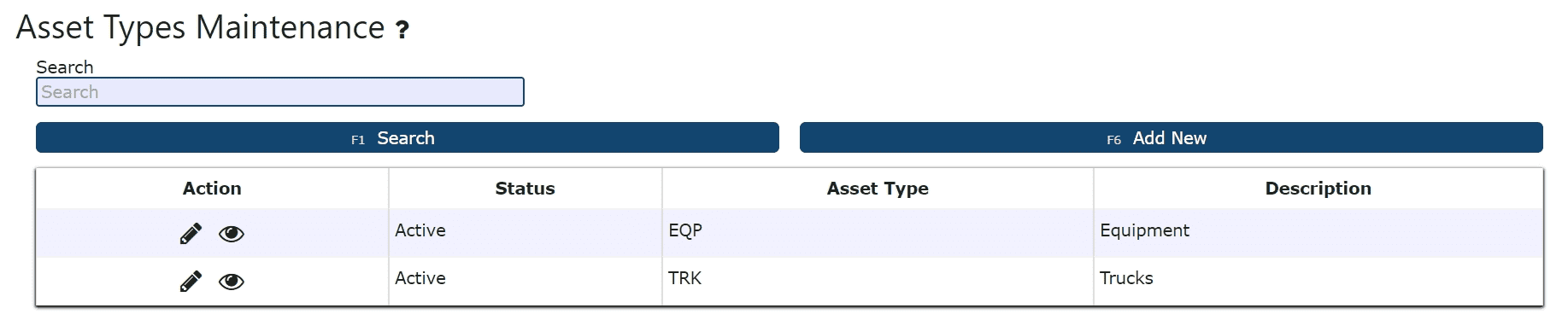

Asset Organization

Asset Types: Group assets into logical categories for simplified reporting and maintenance tracking.

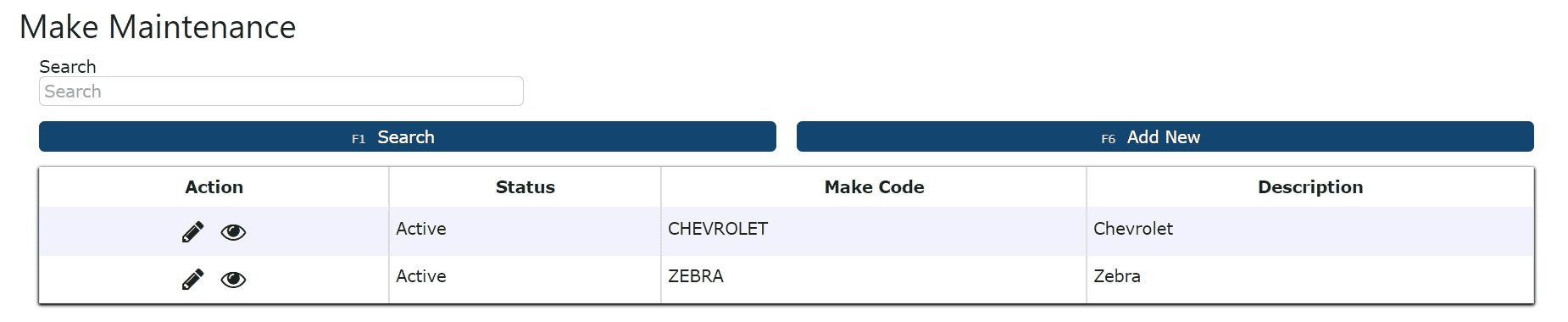

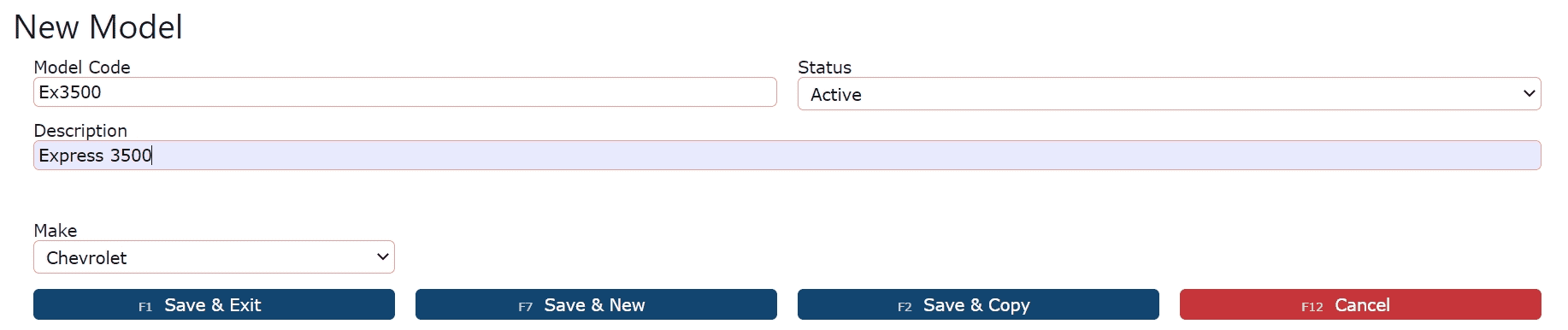

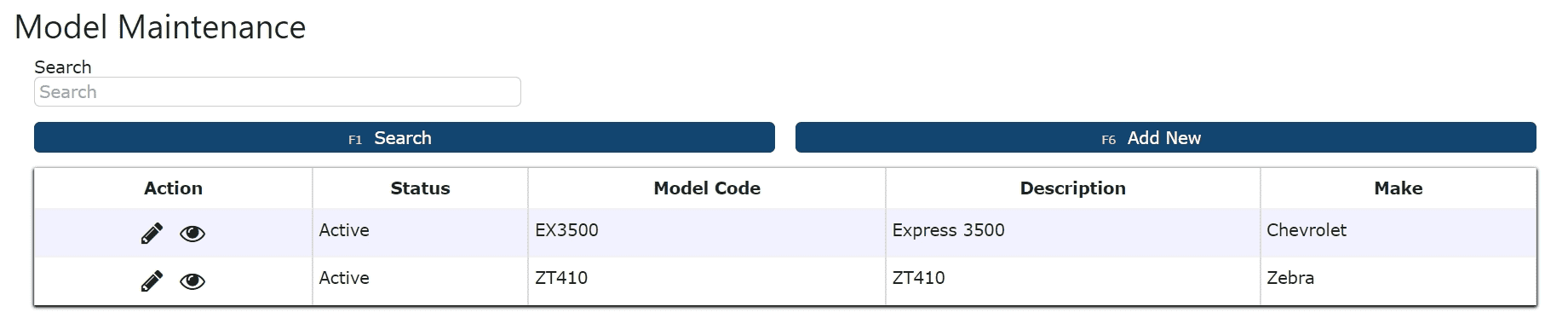

Makes and Models: Record manufacturer and model information for precise identification.

Components: Link specific components (e.g., filters, motors, belts) to each asset for detailed maintenance tracking.

Attachments: Upload related files like receipts, warranty information, and inspection photos.

Examples of Trackable Assets:

• Delivery Trucks

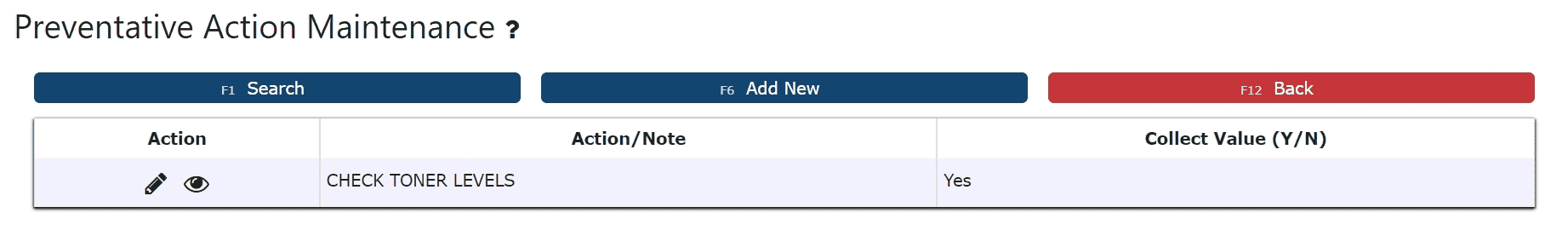

• Printers

• Machinery

Best Practices

• Keep asset records current with up-to-date types, models, and components.

• Set up PM schedules for all critical assets to reduce unplanned downtime.

• Regularly review maintenance events to ensure timely completion and approval.

• Use attachments to centralize documentation for each asset and maintenance event.

• Utilize RF scanning to improve efficiency and maintain audit compliance.