What is Bin Activation?

Bin Activation refers to the process of enabling and configuring bin management within a warehouse to track inventory at the specific storage-location level. When bins are activated, inventory can be organized and monitored by exact locations—such as aisles, rows, or depth—rather than just by warehouse.

This setup allows items to be stored in multiple bins, ensures more accurate stock visibility, improves picking and put-away efficiency, and provides better overall control of warehouse space and inventory movement. When a new bin is created in the system, it must be activated before it can be used for inventory storage or transactions.

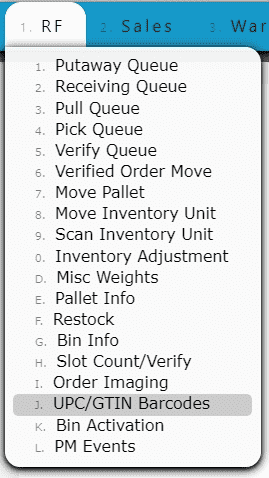

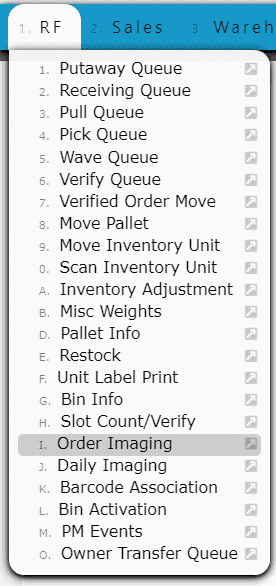

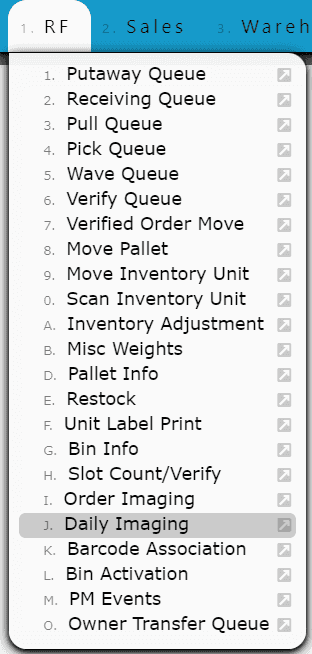

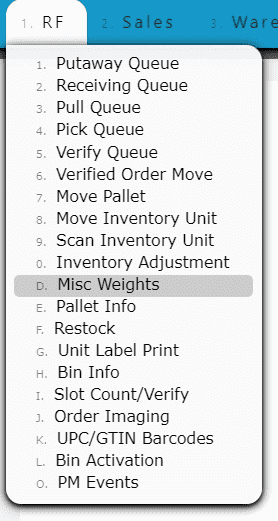

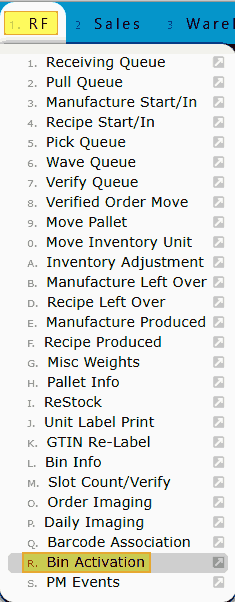

1. Navigate to the Bin Activation screen. From the main menu, go to RF → Bin Activation to begin the activation process.

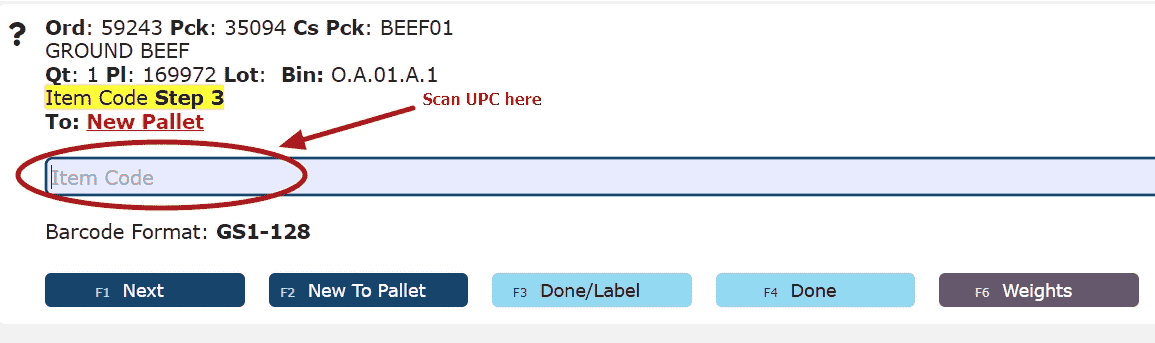

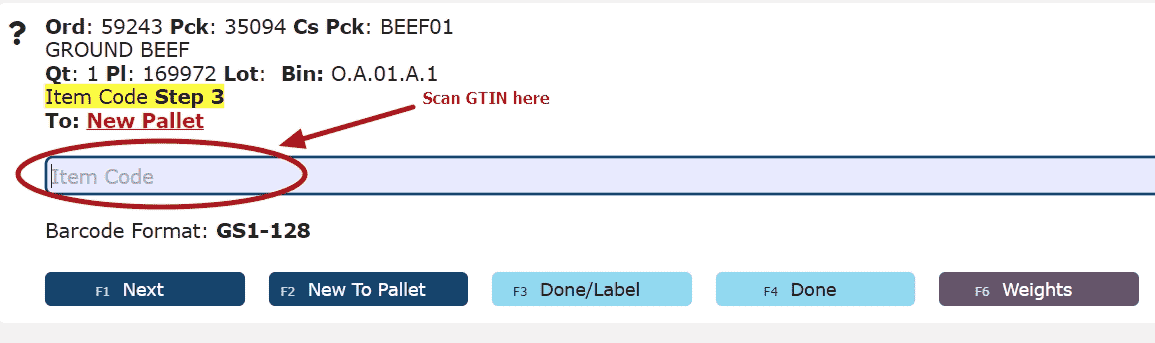

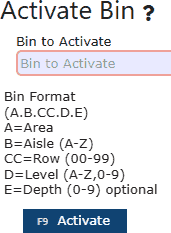

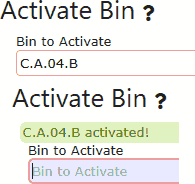

2. Review the Activate Bin page layout. The Activate Bin page includes a text field labeled “Bin to Activate,” along with bin format details displayed on the right-hand side. At the bottom of the screen, you’ll find a large dark blue Activate button to finalize the process.

3. Enter the bin number to activate. Whether the bin was newly created or has been awaiting use, type the bin number into the provided field and select Activate to enable it for use.

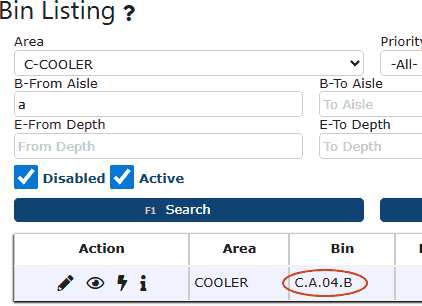

4. Confirm successful activation. Once activated, a green confirmation message will appear. You can verify the bin’s status by navigating to Warehouse → Bins and searching for the bin number—its status will now display as Active.