Disabling an Order Attribute

Disabling an Order Attribute removes it from the list of selectable attributes on new and edited orders while preserving all historical records where the attribute was previously used. This ensures that your organization does not inadvertently apply outdated or irrelevant attributes to future transactions while maintaining accurate reporting, audit trails, and data integrity. Disabling is the recommended approach when an Order Attribute is no longer relevant or needed for current workflows.

Disabling an Order Attribute

You should consider disabling an Order Attribute when:

• It is no longer used in current order workflows.

• The attribute has been replaced by a new or updated value.

• It was created for testing, seasonal use, or a limited purpose.

• You want to prevent users from selecting the attribute on new or updated orders.

Because Order Attributes can appear on historical orders, disabled attributes remain visible in reporting and order history, preserving accuracy.

Steps to Disabling an Order Attribute

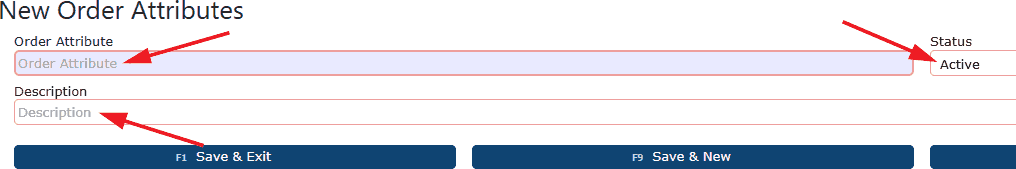

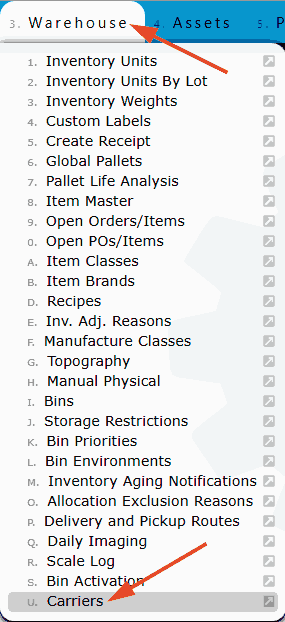

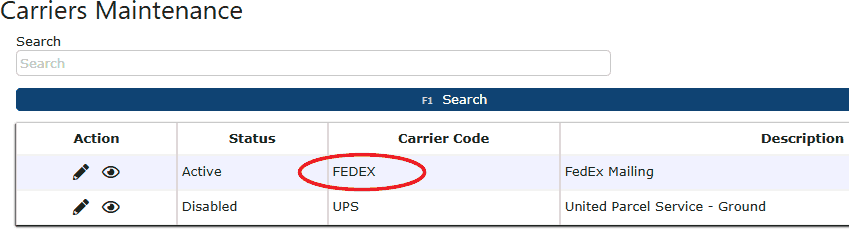

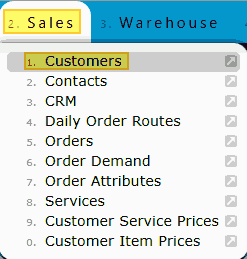

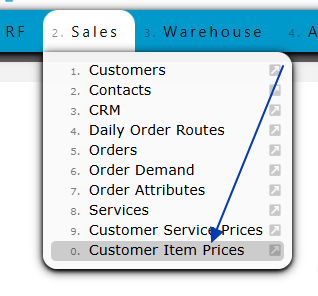

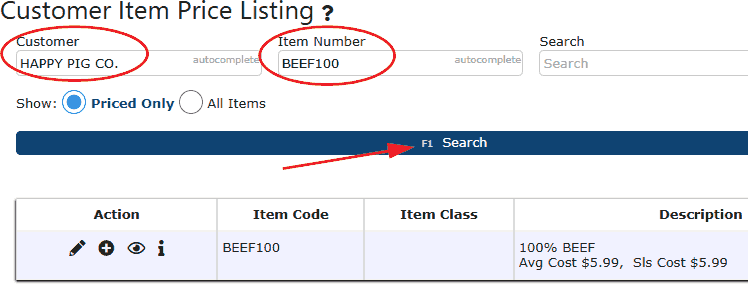

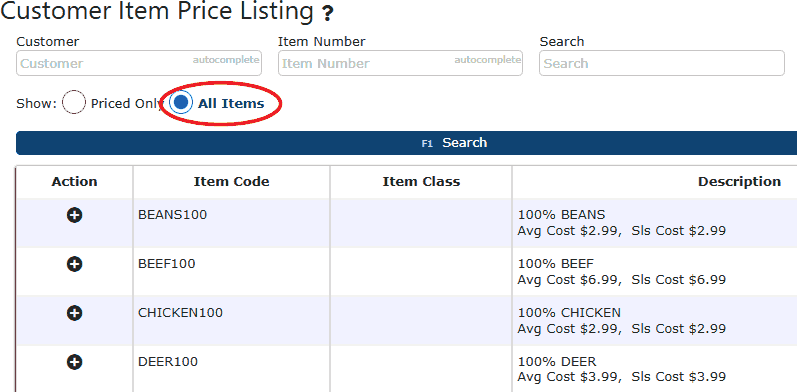

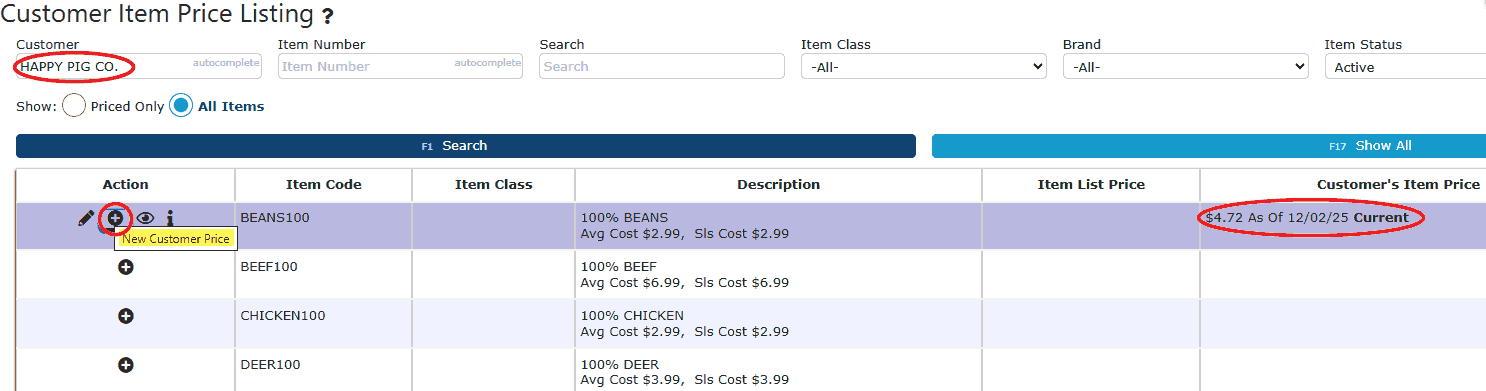

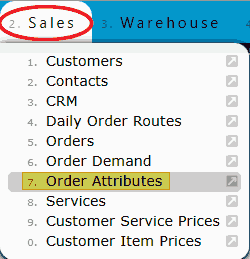

1. Navigate to Sales → Order Attributes.

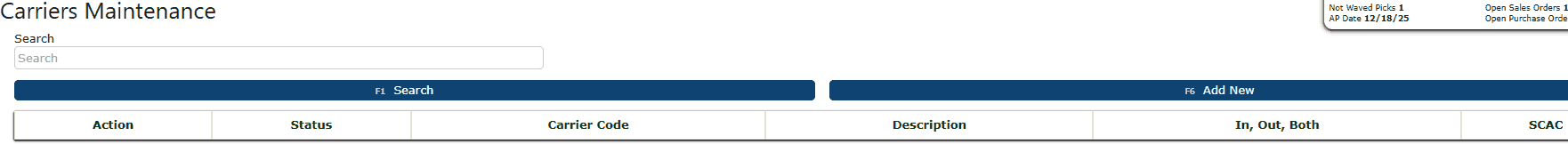

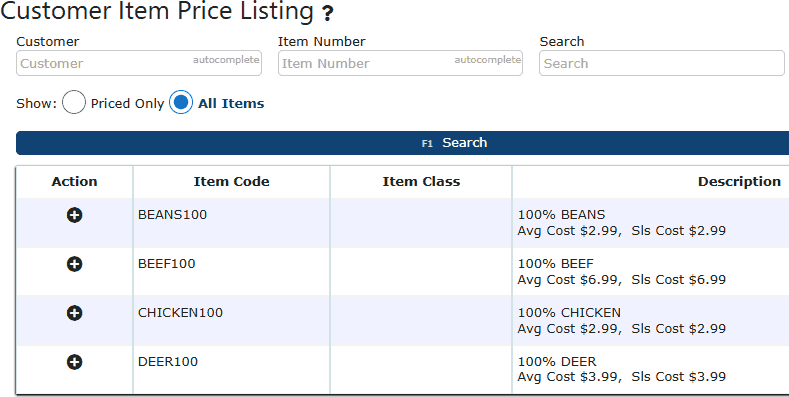

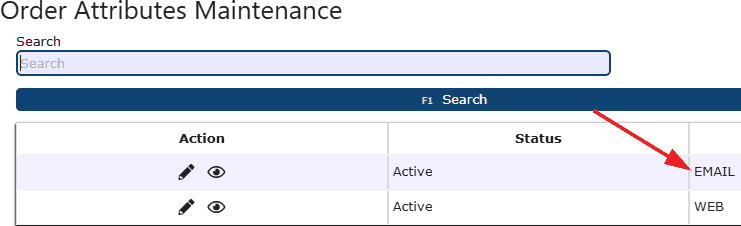

2. The Order Attributes Maintenance screen displays all existing attributes.

3. Locate the Order Attribute you want to disable in the list. Use the Search field to quickly find the attribute by name or description if needed.

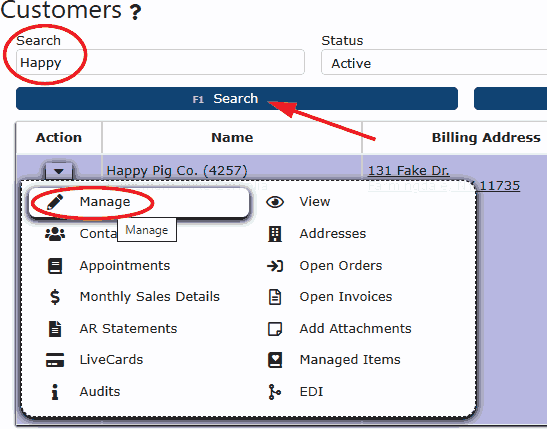

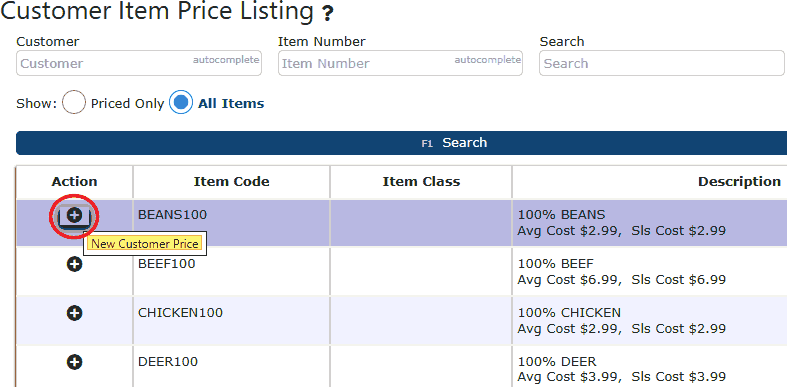

4. Click the Manage (Pencil) icon in the Action column next to the desired Order Attribute.![]()

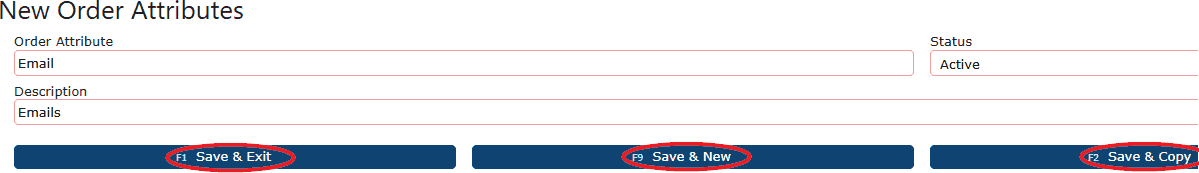

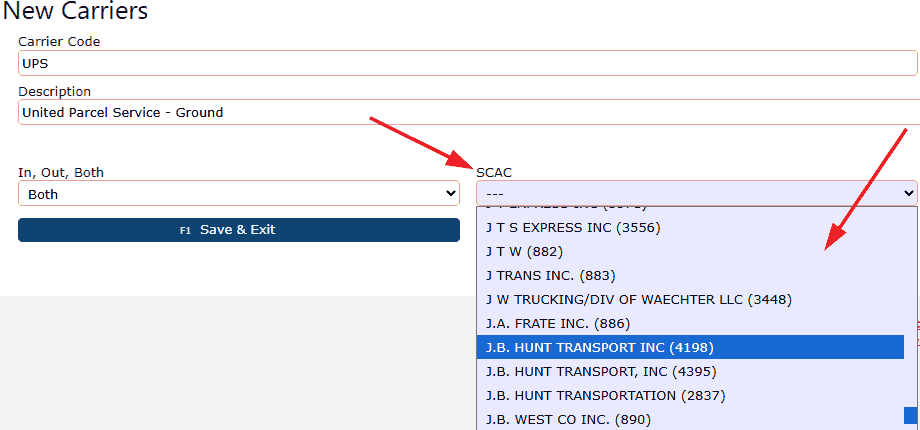

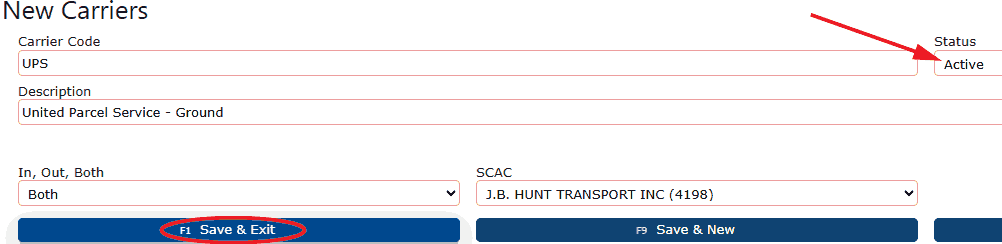

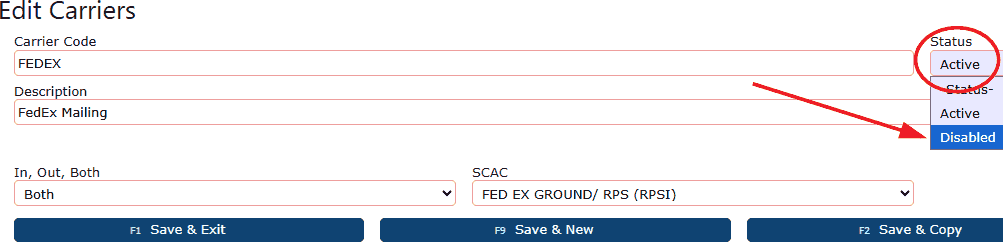

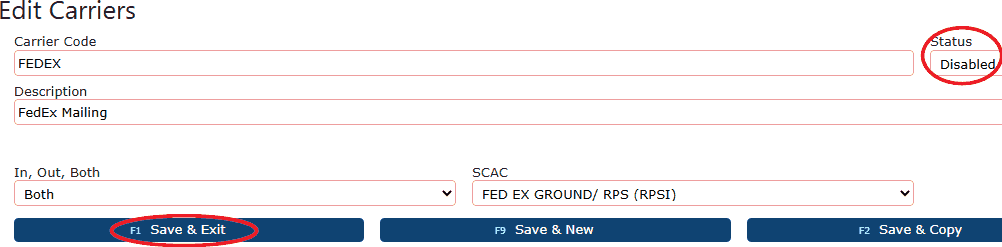

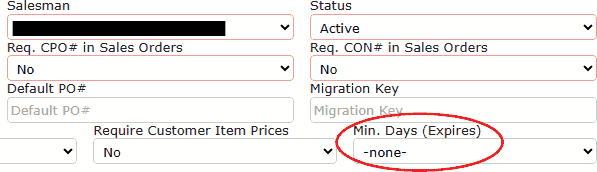

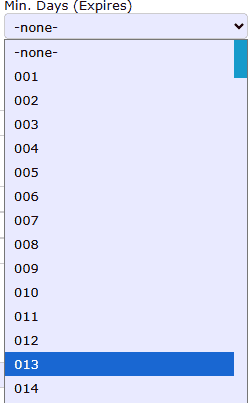

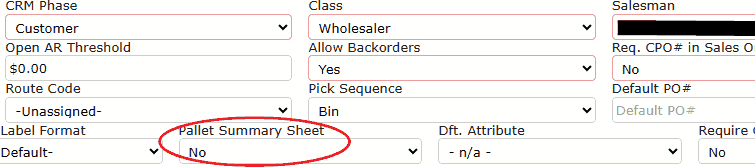

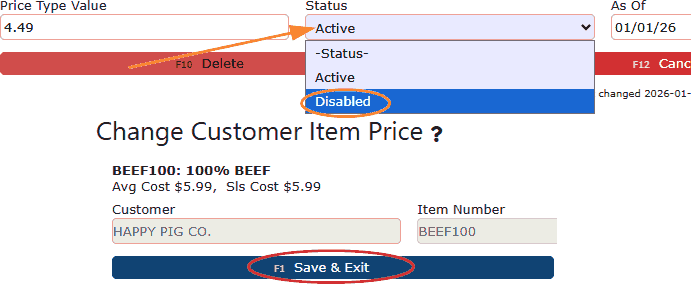

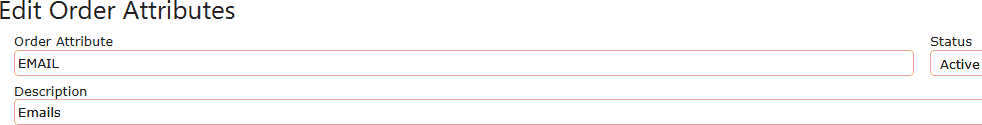

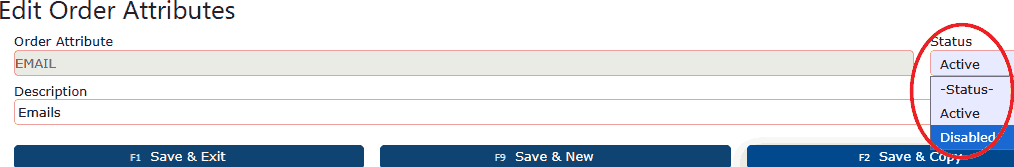

5. In the Edit Order Attribute screen, find the Status dropdown.

6. Change Status from Active to Disabled.

7. Click Save & Exit to apply the change. Once disabled, the attribute will no longer appear as a selectable option when creating or editing orders.

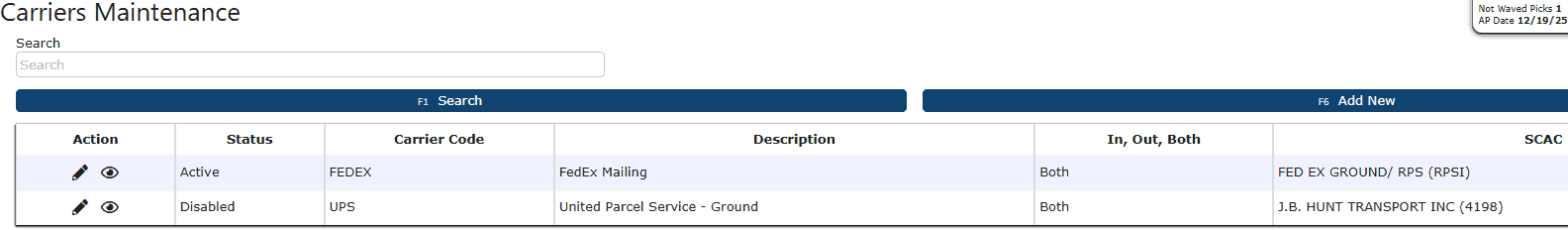

Behavior After Disabling

After an order attribute has been disabled:

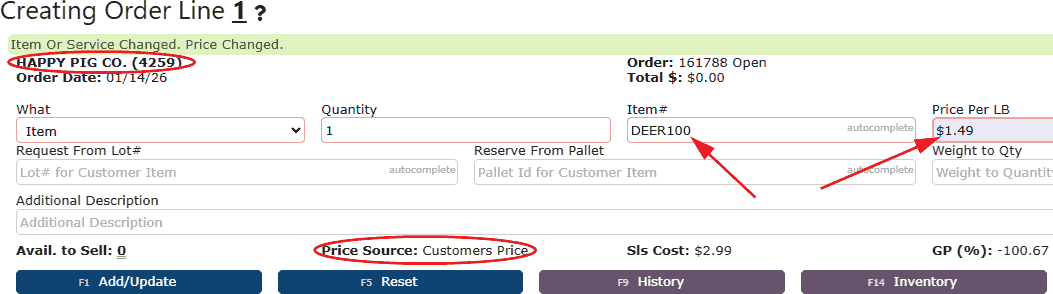

• It is removed from all drop-down lists when selecting an attribute on new orders.

• Users cannot apply the disabled attribute to any new or edited orders.

• The attribute remains on historical records where it was previously used and continues to appear in reports and filters related to past order activity.

• Disabled attributes will not interfere with order processing or reporting, but they will not be available for new transactions.

Why Disabling is Better Than Deleting

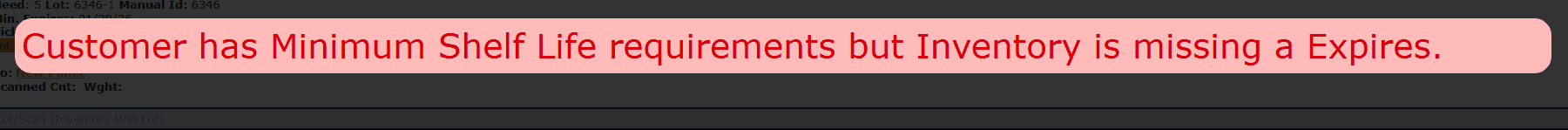

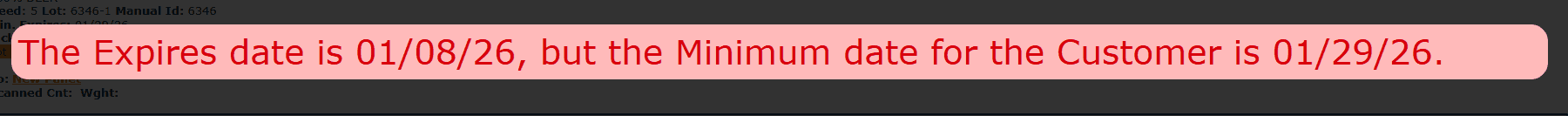

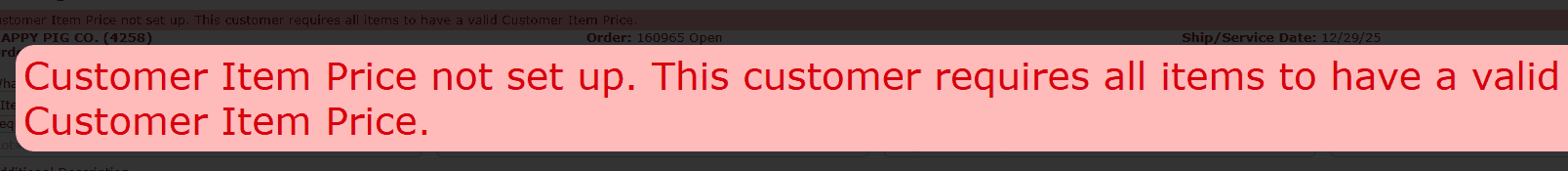

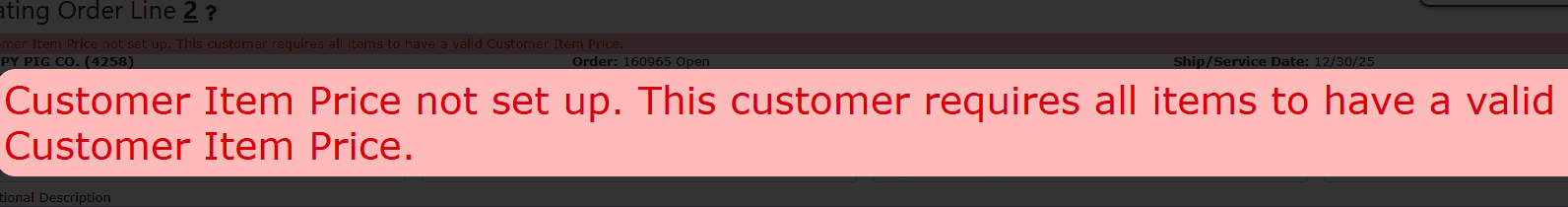

Order Attributes that have been used on customer orders cannot be deleted, regardless of whether the associated sales orders are still open, closed, or already invoiced. If you attempt to delete an Order Attribute that is tied to existing order records, the system will display a red hard-stop error message: "This record cannot be deleted. Order record(s) exist."

This safeguard prevents the removal of attributes that are already linked to transactional data and ensures the integrity of historical and financial records. For this reason, disabling an Order Attribute is the correct and recommended approach when an attribute is no longer needed. Disabling allows you to:

• Prevent the attribute from being selected on new or edited orders

• Maintain accurate historical order, invoice, and reporting data

• Avoid system errors caused by attempting to delete an attribute in use

• Keep your active Order Attribute list clean and relevant without impacting past transactions

Disabling ensures operational consistency while preserving all existing order history tied to the attribute.