Purchase Order Key Information

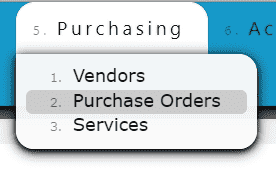

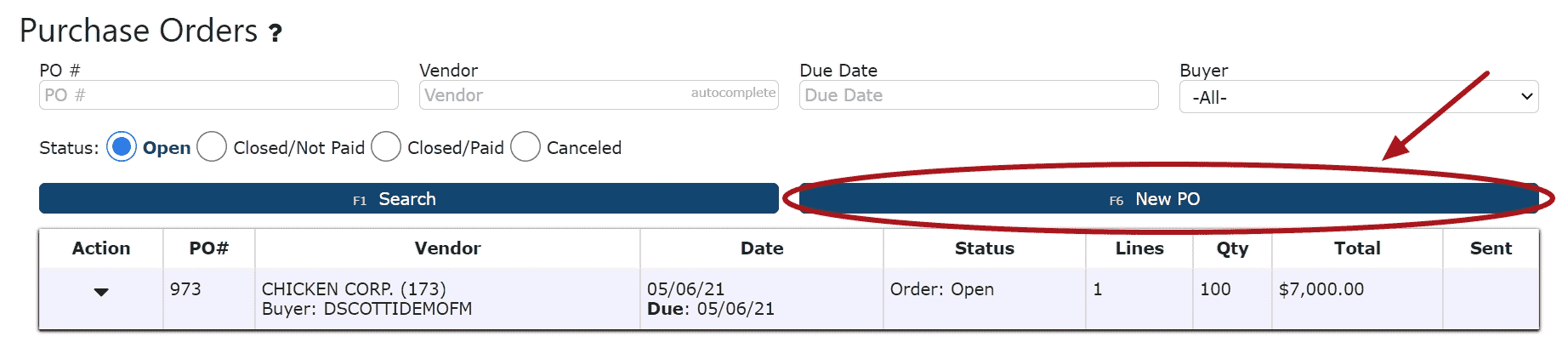

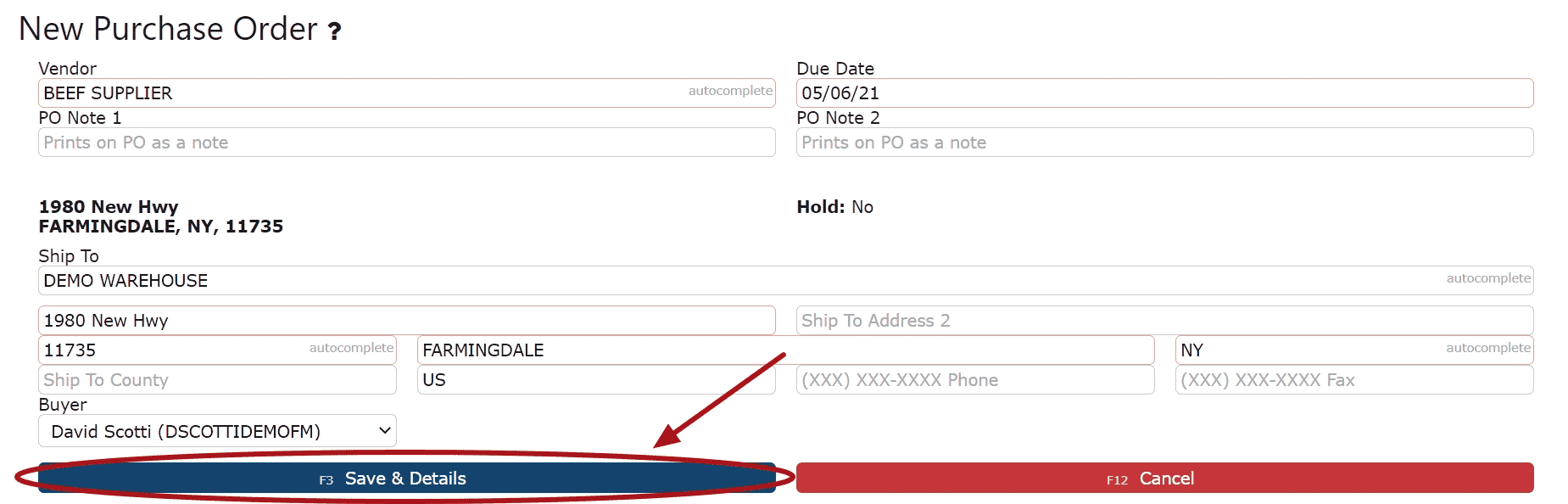

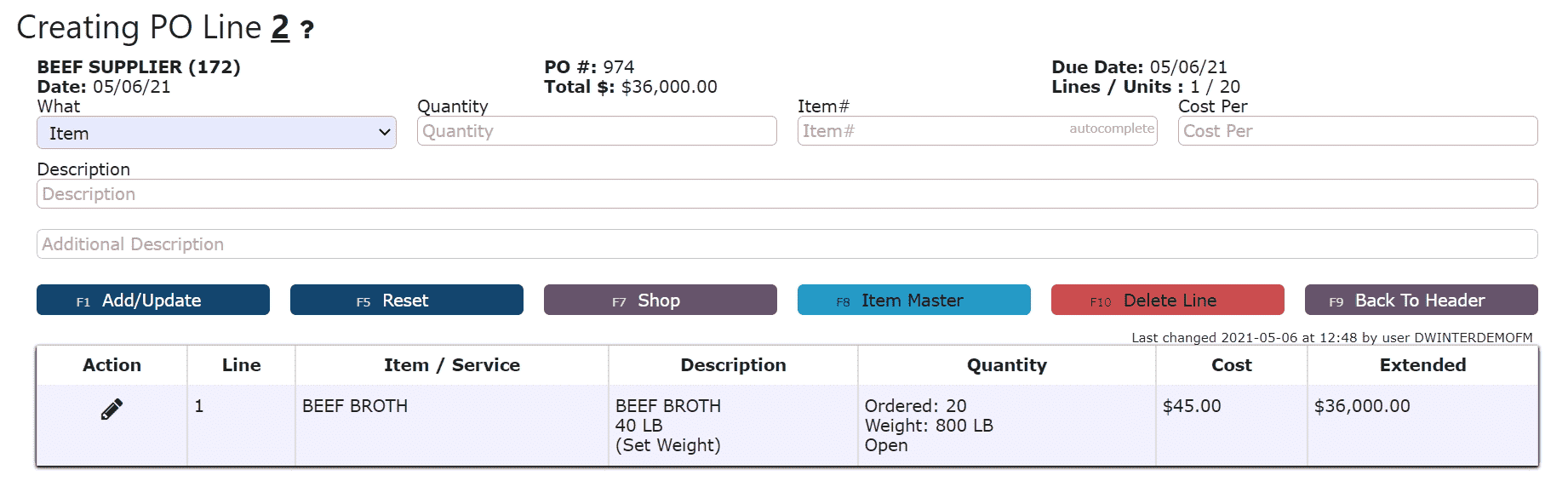

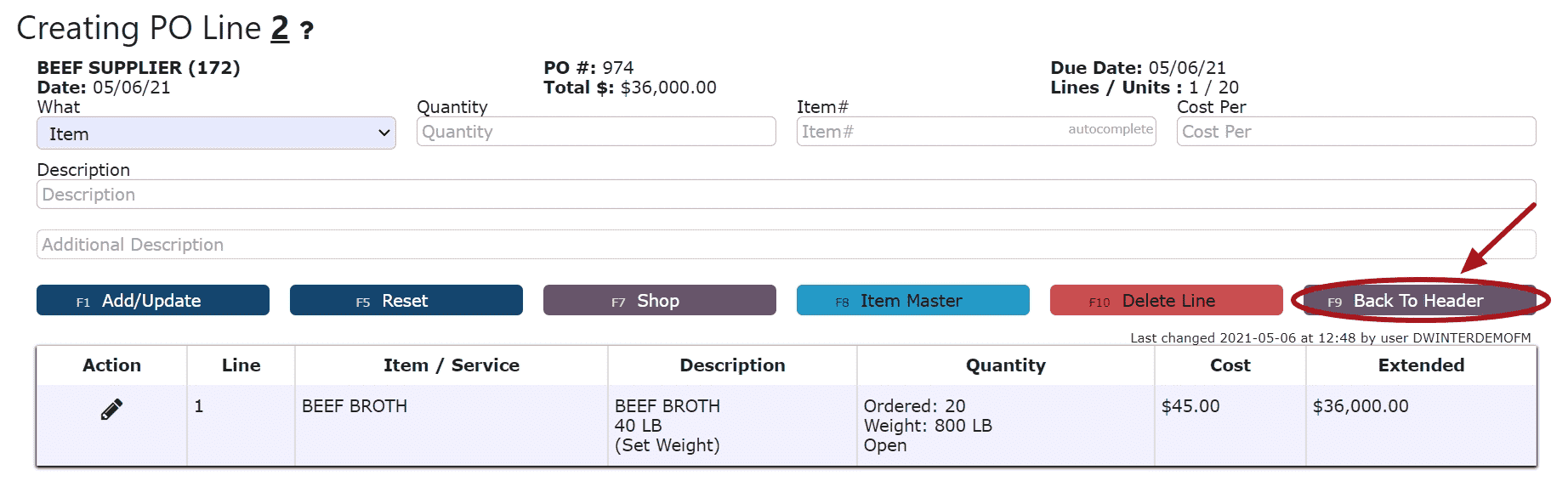

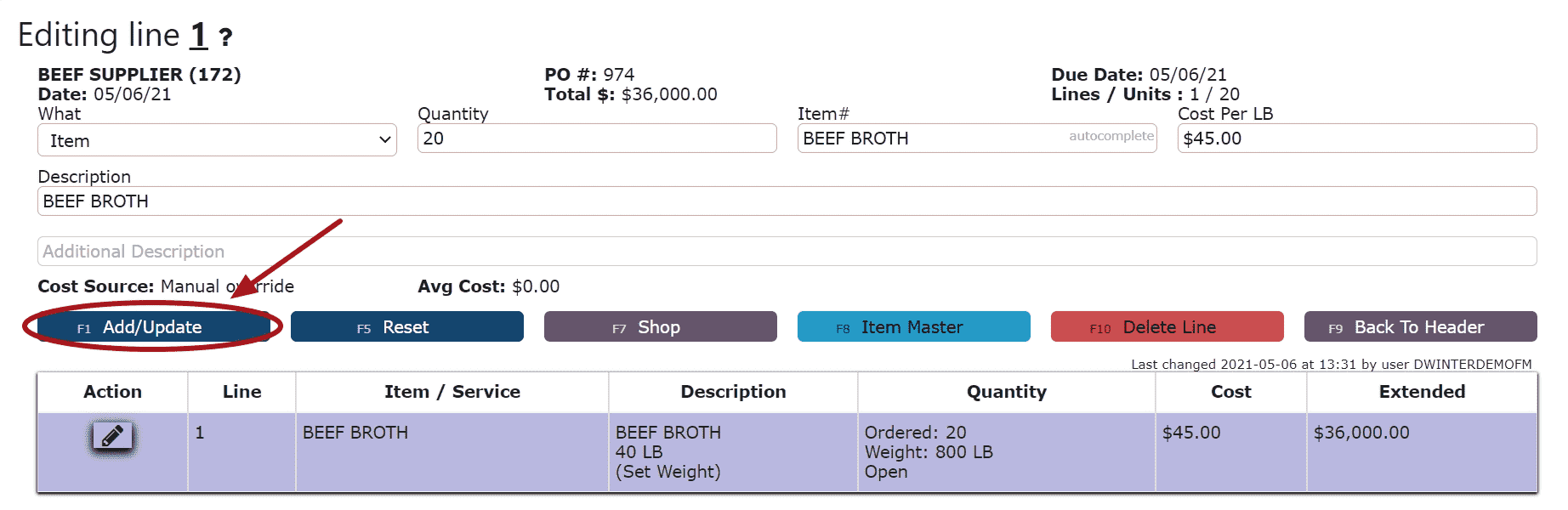

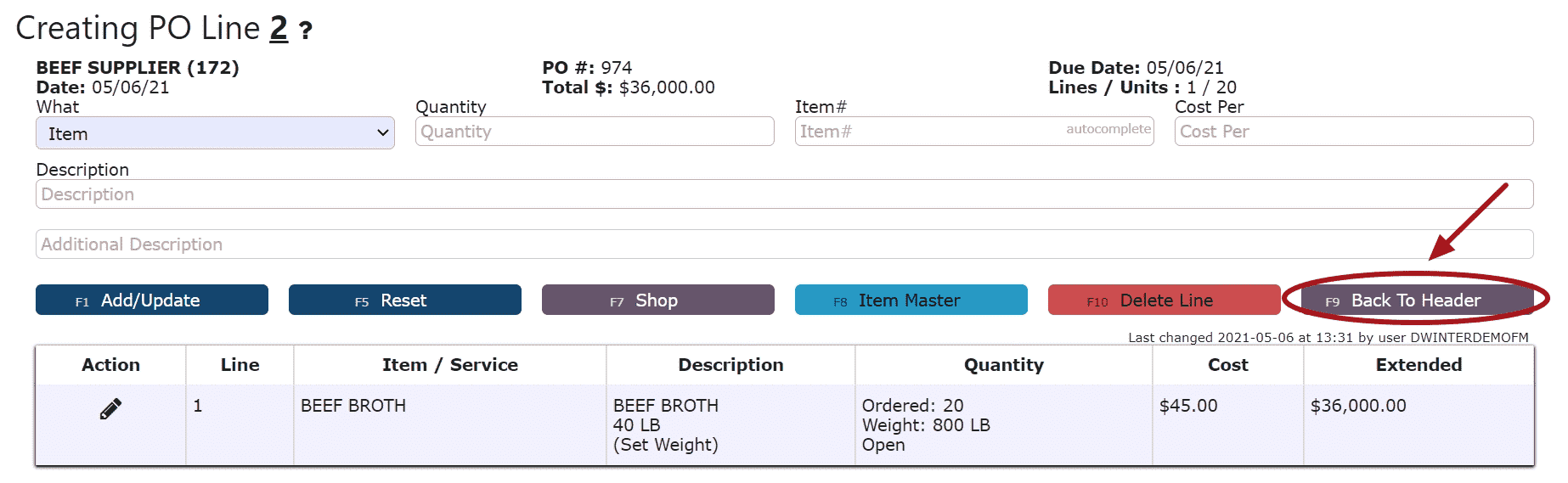

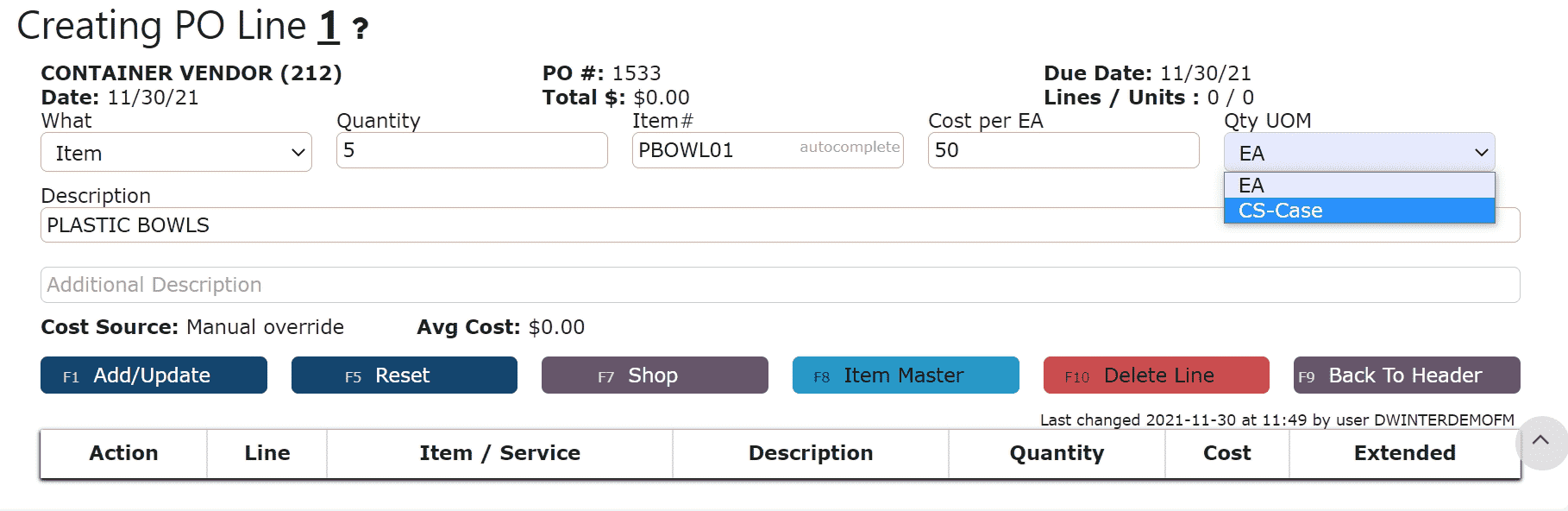

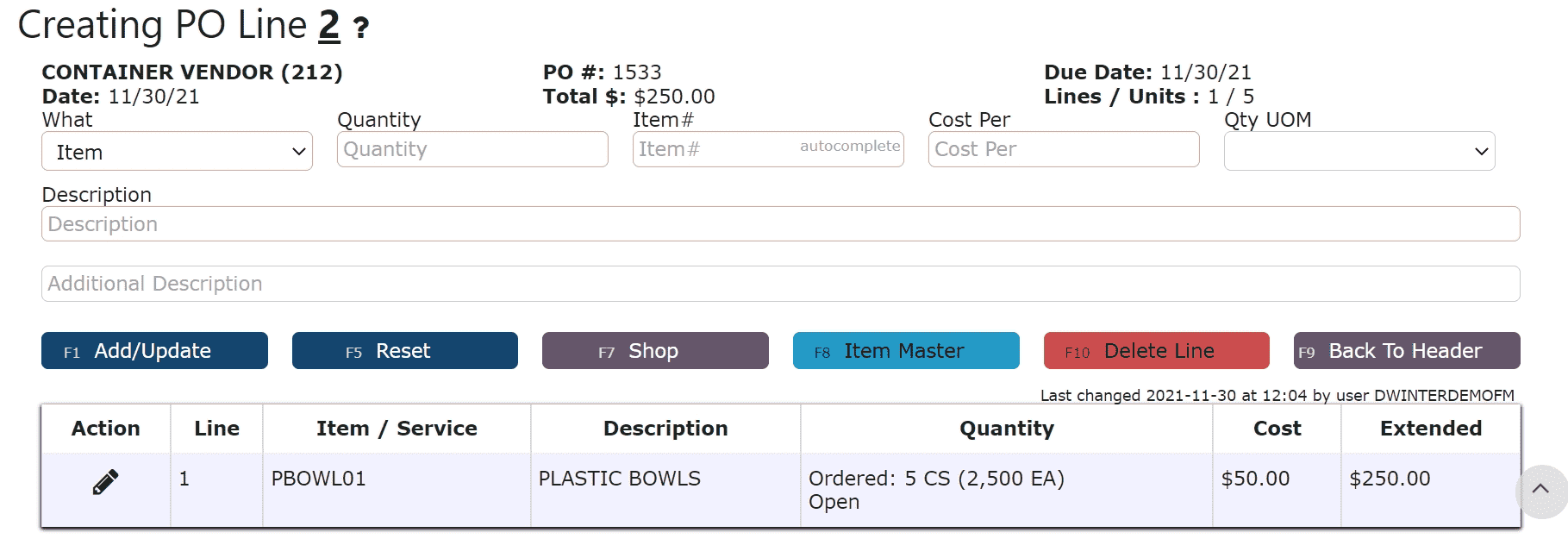

The Purchase Orders feature in Inspired ERP enables users to create, manage, and track purchase orders for both goods and services in one centralized location. This tool supports the entire procurement lifecycle — from initial order creation and receipt through closing and payment — ensuring accuracy, visibility, and control over purchasing activities.Purchase orders in Inspired serve as the foundation for vendor communication, cost tracking, and inventory control. Users can attach supporting documents, record internal notes, clone existing orders, and even shop from past purchases to simplify reordering. Each PO document type is designed to streamline communication between purchasing, warehouse, and accounting teams.

Core Capabilities

Our Purchase Order module provides a variety of tools to simplify and enhance the buying process:

• Attachments & Notes: Add reference files or internal comments directly to a PO for improved traceability and communication.

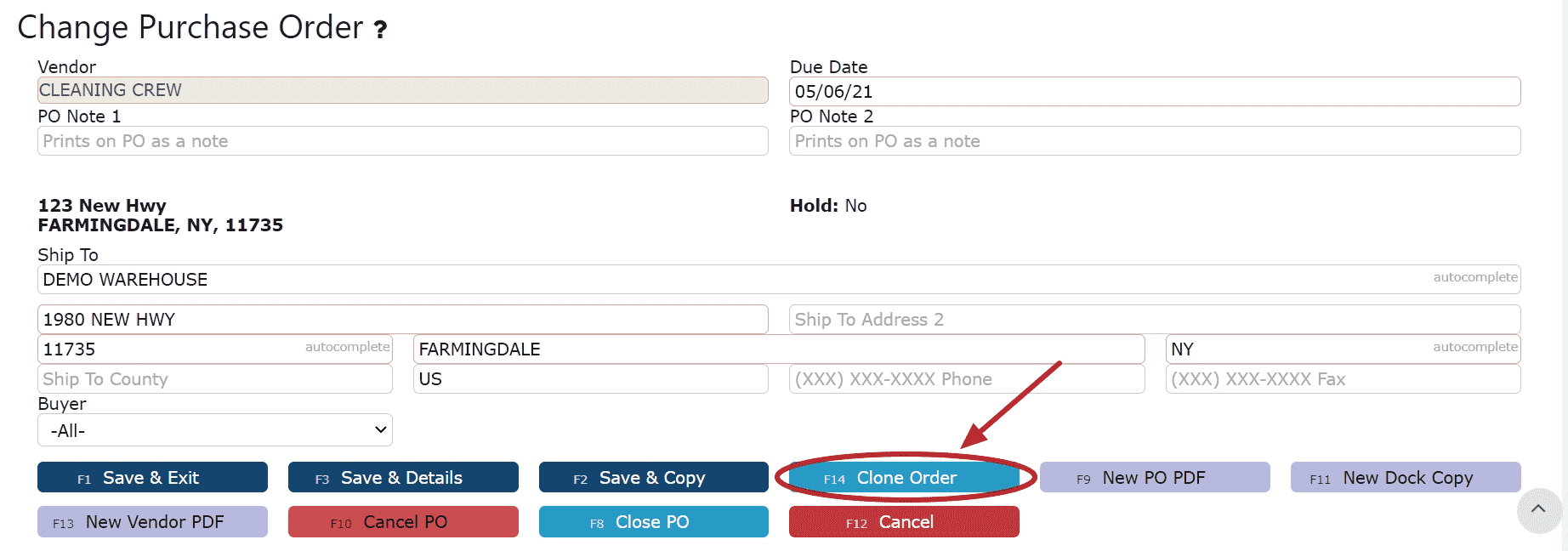

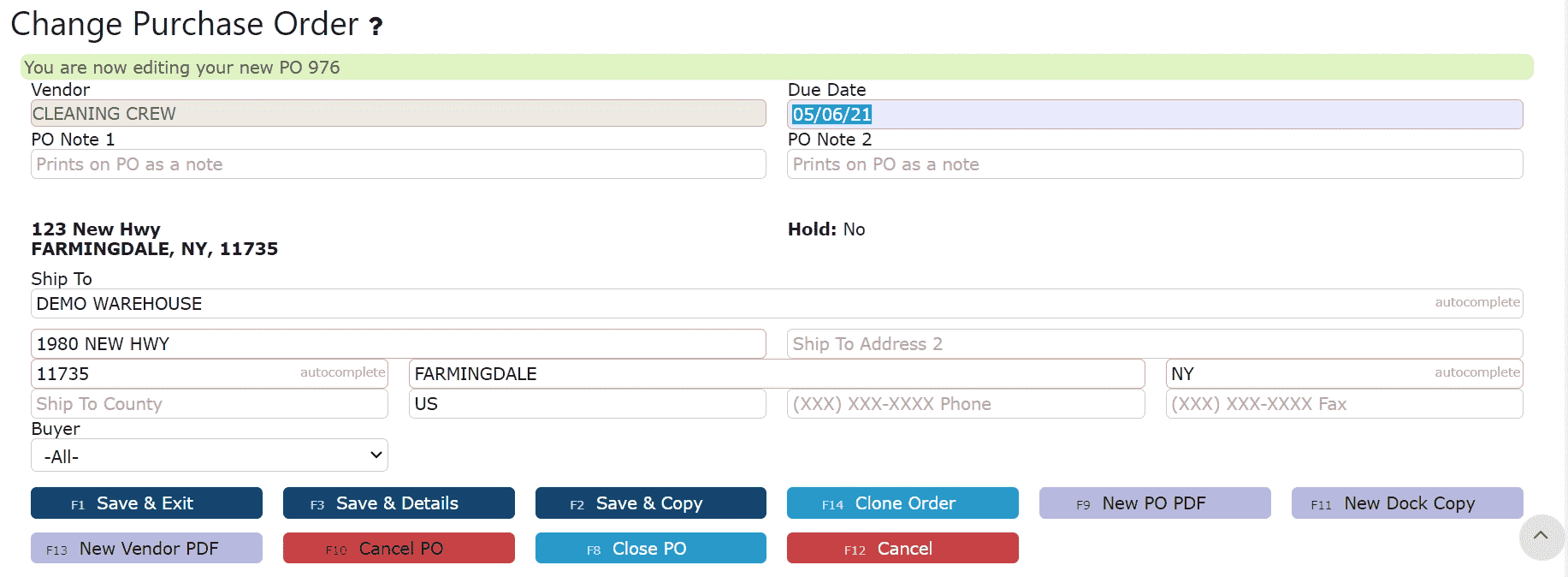

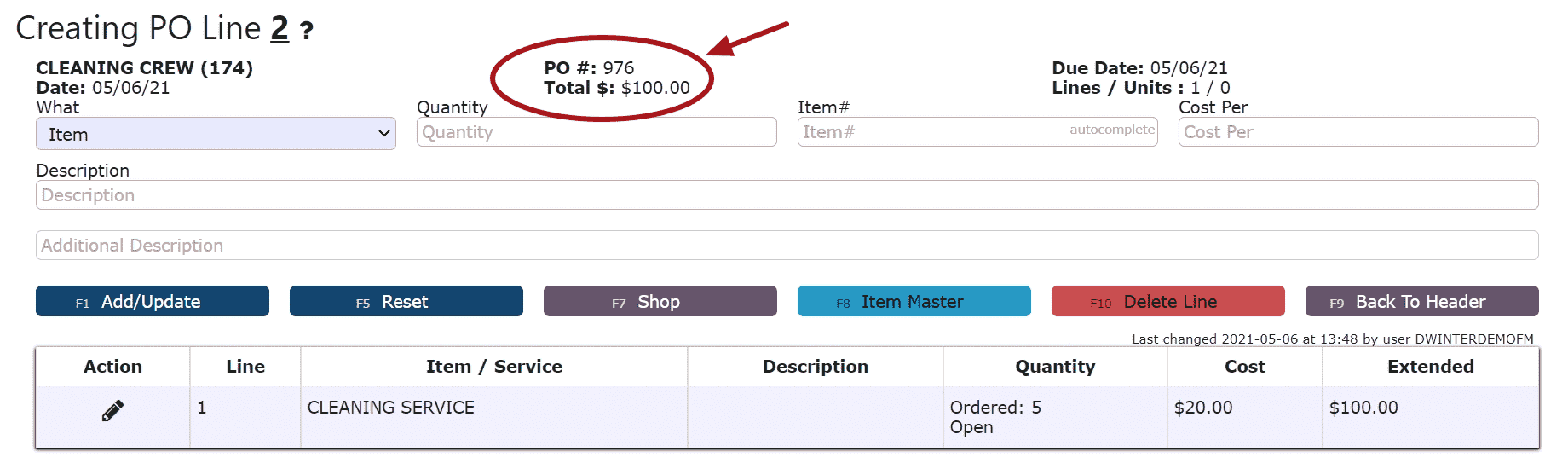

• PO Cloning: Duplicate an existing purchase order to quickly generate new orders with similar details.

• Past Purchase List Shopping: Access previous order data to expedite repeat purchases or vendor-specific items.

These features work together to reduce manual data entry, maintain purchasing consistency, and ensure accurate order documentation.

Purchase Order Documents

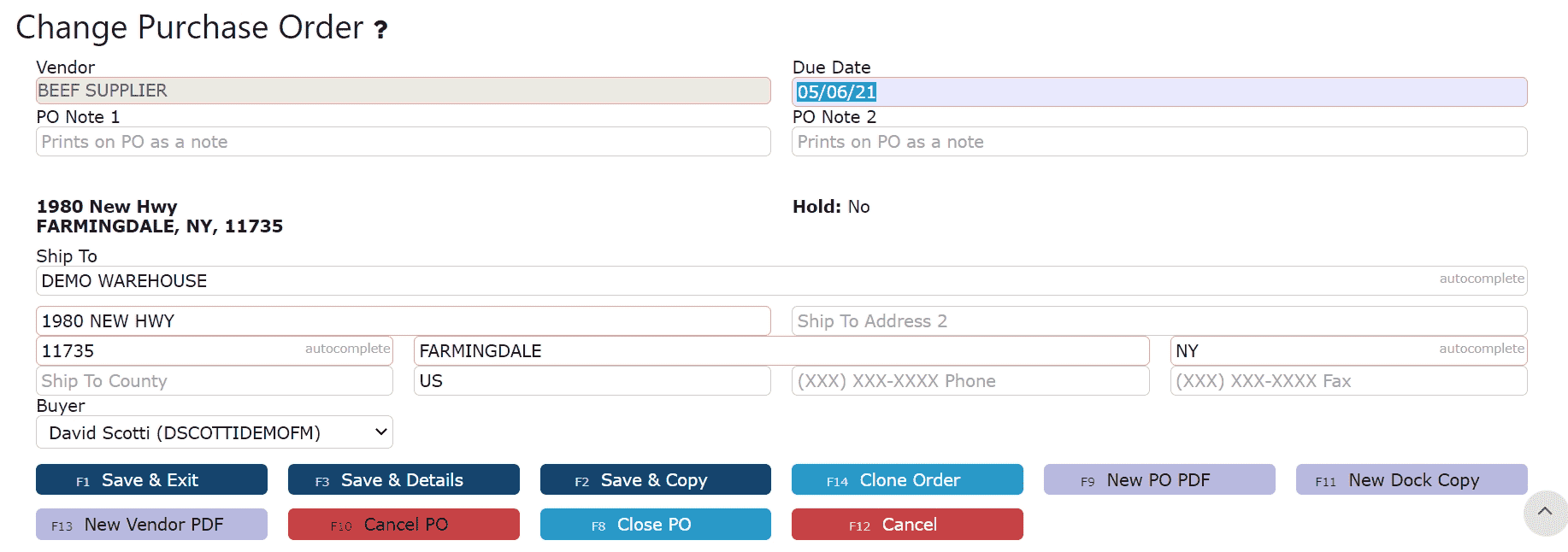

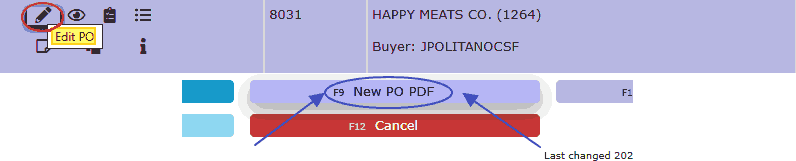

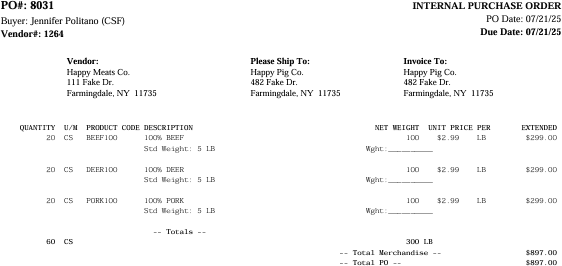

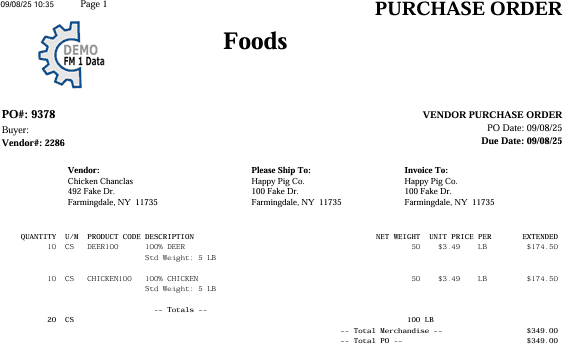

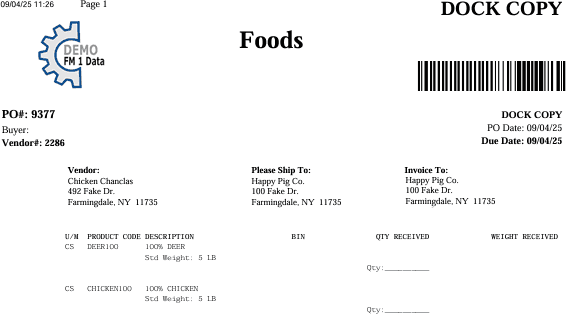

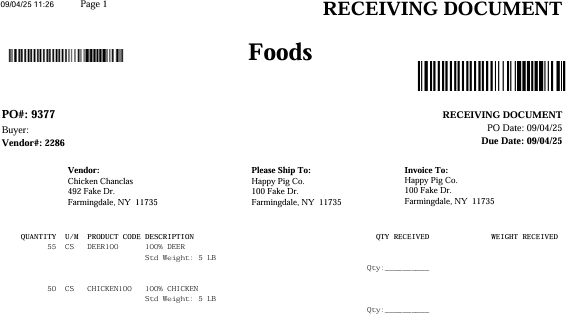

Every PO in Inspired can generate a variety of document formats, supporting both internal processes and external communication with vendors:

• PO PDF: A detailed record of the purchase order, used for internal review and documentation.

• Vendor PDF: A mirror version of the PO PDF that can be automatically emailed to vendors and their contacts.

• Dock Copy: A warehouse-facing document that lists expected items with blank quantities, used during receiving for accurate check-in and verification.

These documents ensure that all departments — purchasing, warehouse, and accounting — have clear and consistent reference materials for each transaction.

Best Practices

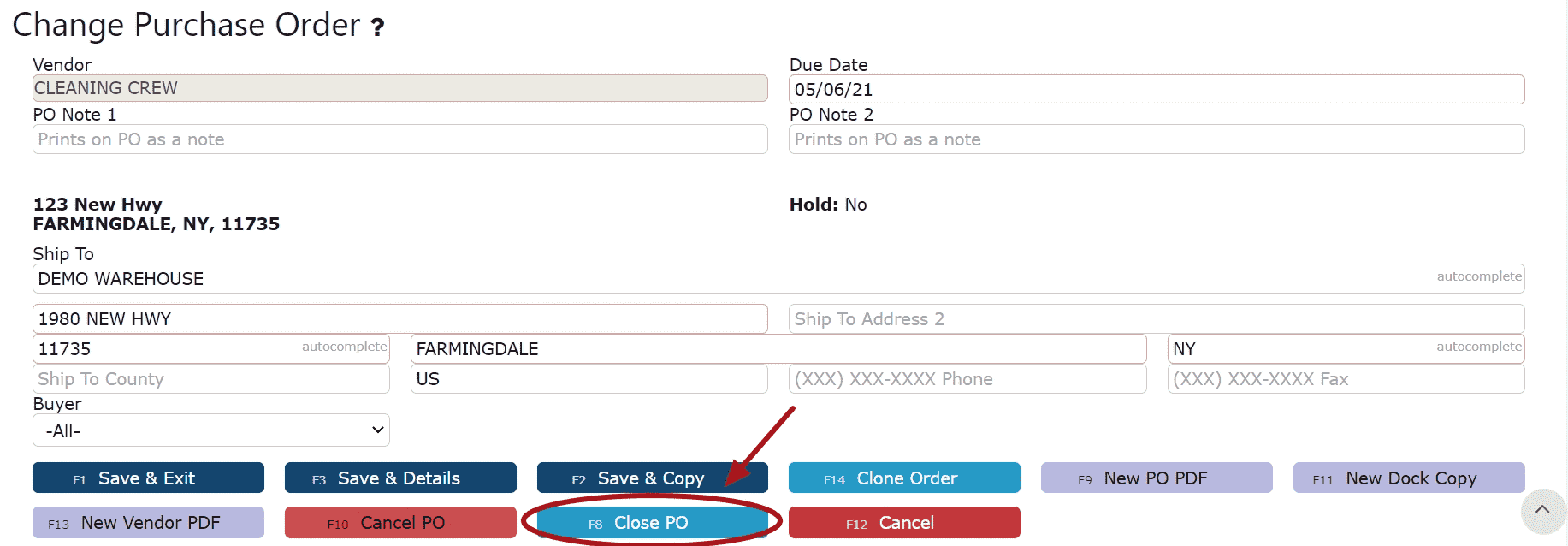

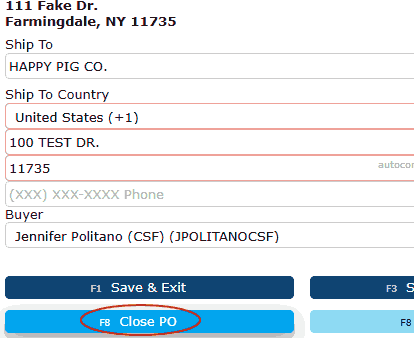

• Regularly review open and partially received POs to ensure timely closure and payment.

• Leverage PO cloning for repeat orders to maintain consistency and save time.

• Use Dock Copies to prepare warehouse teams before deliveries arrive, ensuring smooth receiving and reduced discrepancies.

• Attach relevant files or notes to maintain a complete audit trail and support future vendor or pricing reviews.